Sewing Machine Needle Sizes, Types & Uses Guide (with Tables)

Answering the crucial question, “What is the right sewing machine needle sizes, types?” becomes the gateway to achieving flawless stitching results. Selecting the appropriate sewing machine needle sizes and types is not only about preventing broken threads and skipped stitches but also about elevating your projects to a professional standard.

This comprehensive guide is designed to empower seamstresses with valuable insights into the intricacies of needle selection, covering various sizes and types. Dive into the world of sewing machine needles through this article, where we unravel the mysteries of needle thicknesses and provide you with indispensable tables showcasing the ideal needle choices for different projects.

Elevate your sewing experience and ensure your stitches are not just functional but also aesthetically pleasing.

Sewing Machine Needle Sizes Tutorial

Understanding the nuances of sewing machine needle sizes and types is pivotal for achieving impeccable results in your projects. This tutorial delves into the factors influencing needle selection, emphasizing the importance of choosing the right size to maintain proper tension and avoid issues like puckering and skipped stitches.

What Is A Sewing Machine Needle?

A sewing machine needle is a precision tool crafted for electronic sewing machines. Its design includes a pointed tip with a thread-inserting hole, a blunt top featuring a rounded front and flat back, securely held in place by a screw in the machine.

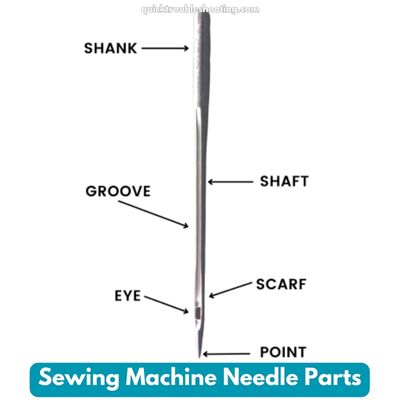

Sewing Machine Needle Parts

- Butt: The part inserted into the sewing machine clamp.

- Shank: With a round front and flat back, facilitating correct needle orientation in the machine.

- Shaft: The needle’s length, determining its reach.

- Eye: Where the thread is threaded through.

- Tip: The pointed end responsible for piercing fabrics.

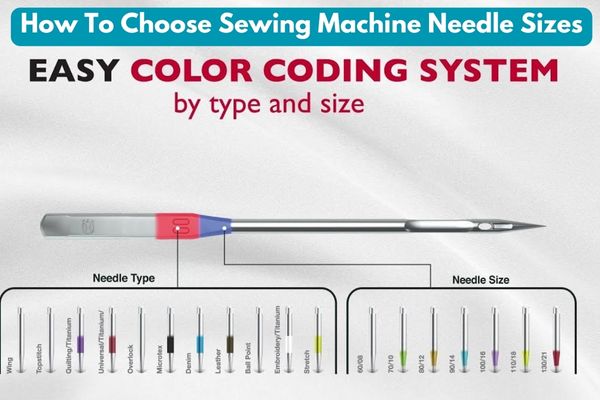

How To Choose Sewing Machine Needle Sizes

Choosing the right sewing machine needle size is a crucial step in ensuring the success of your sewing projects. Needle selection depends on two key characteristics: thickness and purpose.

Understanding these aspects will empower you to match the needle to your fabric and sewing requirements.

Factors Influencing Sewing Needle Sizes:

- Thickness: Sewing machine needle sizes vary based on thickness. Thicker needles are designed for heavier fabrics, while thinner needles excel with delicate materials like silk and chiffon.

- Purpose: Consider the needle’s purpose, whether for sewing stretch fabrics, topstitching, working with denim, or piercing leather. Different fabrics and purposes may necessitate needles with varied tip shapes to effectively penetrate fabric fibers.

A Quick Table for Sewing Machine Needle Sizes:

| Fabric Type | Needle Size | Needle Purpose |

|---|---|---|

| Lightweight Fabrics | 60/8 – 75/11 | Universal, Fine |

| Medium Weight Fabrics | 80/12 | Topstitching |

| Heavyweight Fabrics | 90/14 – 100/16 | Denim, Quilting |

| Delicate Fabrics | 60/8 – 70/10 | Silk, Chiffon |

| Stretch Fabrics | 75/11 – 90/14 | Stretch, Knits |

| Leather | Specialized | Leather |

Additional Resources: Hand Sewing Machine Needle Sizes

For further insights into hand sewing machine needle sizes, explore our in-depth resources to refine your understanding and master the art of needle selection. Elevate your sewing experience by making informed choices tailored to your specific fabrics and projects.

Sewing Machine Needle Brands

Selecting the right sewing machine needle brand is paramount for a seamless and worry-free sewing experience. Quality plays a crucial role, and several reputable brands stand out for their strong and durable needles. Consider investing in needles from the following brands to enhance the overall quality of your sewing projects:

| Brand | Features |

|---|---|

| Klasse | Known for durability and reliability. |

| Singer | Renowned for a wide range of needle options. |

| Schmetz | Trusted for precision and longevity. |

Choosing needles from these respected brands ensures that your sewing endeavors are met with robust tools, minimizing the risk of breakage and contributing to the excellence of your projects. Invest wisely in the right needle to elevate the overall quality of your sewing craftsmanship.

What Do The Numbers Mean For Sewing Machine Needle Sizes?

Understanding the numbers on needle packaging is key to selecting the right needle for your sewing project. The two numbers, separated by a “/”, provide information about the American and European size systems.

For instance, 80/12 indicates that the smaller number (80) corresponds to the American size system (ranging from 8 to 20), while the larger number (12) pertains to the European size system (ranging from 60 to 120).

American Needle Numbers and Diameter

In the American size system for sewing machine needles, the smaller number on the packaging corresponds to the needle’s thickness, ranging from 8 to 20. Unlike the European system, the American numbers do not directly represent the needle’s diameter.

Instead, a lower number indicates a thinner needle, suitable for lighter fabrics, while a higher number signifies a thicker needle designed for heavier materials. This system offers a practical way to match needle sizes with the fabric weight, ensuring optimal stitching results in various sewing projects.

European Needle Numbers and Diameter

In the European size system, the numbers represent the diameter of the needle. A needle with a 1mm diameter is labeled as 100. This system allows you to gauge the thickness of the needle more precisely.

Sewing Machine Needle Sizes Explained

In simple terms, the larger the number on the needle, the thicker the needle. This correlation is vital for achieving optimal results in your sewing endeavors. Use smaller needle sizes, like 60/8 or 70/10, for lightweight fabrics, and opt for larger sizes, such as 100/16, when working with heavyweight fabrics.

What Are the Most Common Sewing Machine Needle Sizes?

Here’s a comprehensive table with additional key data for some of the most common sewing machine needle sizes:

| European | US Size | Labeling | Ideal Use | Needle Type |

|---|---|---|---|---|

| 60 | 8 | 60/8 | Lightweight fabrics | Universal |

| 65 | 9 | 65/9 | Lightweight fabrics | Universal |

| 70 | 10 | 70/10 | Light to medium fabrics | Universal |

| 75 | 11 | 75/11 | Light to medium fabrics | Universal |

| 80 | 12 | 80/12 | Medium weight fabrics | Universal |

| 90 | 14 | 90/14 | Medium to heavy fabrics | Universal/Jeans |

| 100 | 16 | 100/16 | Heavyweight fabrics | Quilting/Denim |

| 110 | 18 | 110/18 | Heavyweight fabrics | Quilting/Denim |

Refer to this comprehensive table when choosing your sewing machine needles, considering not just the size but also the ideal use and recommended needle types for different fabrics.

This ensures that you match the needle precisely to your project requirements, guaranteeing professional and flawless results in your sewing endeavors.

What Sewing Machine Needle Sizes Should I Use?

Deciphering the numbers on sewing machine needle packages is pivotal for achieving precise and professional stitching results. The numbers denote the thickness of the fabric that the needles are designed to sew.

Understanding this correlation allows you to match the needle size with the fabric weight for optimal outcomes in your sewing projects.

Detailed List of Sewing Needle Sizes and Suitable Fabrics:

- Size 8/60, 9/65, 10/70 – Very Fine Fabrics: Ideal for fine silk, chiffon, organza, voile, and fine lace.

- Size 11/75, 12/80 – Lightweight Fabrics: Recommended for cotton voile, silk, synthetics, spandex, and lycra.

- Size 14/90 – Medium Weight Fabrics: Use for quilting fabrics, cotton, velvet, fine corduroy, linen, muslin, jersey, tricot, knits, light wool, sweatshirt knits, and fleece.

- Size 16/100 – Heavy Weight Fabrics: Designed for denim, corduroy, canvas, heavy linens, heavy twill, duck, suiting, and leather.

- Size 18/110 – Very Heavy Fabrics: Tailored for heavy denim, heavy canvas, upholstery fabric, and faux fur.

Assorted Needle Packs for Versatility

To accommodate a variety of projects, consider purchasing assorted packs of sewing needles. These packs typically include different sizes, allowing you to easily switch to a suitable needle for each specific task.

For example, if you frequently work with quilting cotton fabric, having a selection of 80/12 and 90/14 needles readily available in your sewing drawers ensures you’re well-equipped for different fabric weights and project requirements.

Types Of Sewing Machine Needles

Understanding sewing machine needle sizes is crucial, but equally important is identifying the type of needle suited for specific fabrics. This detailed exploration covers the most common sewing machine needle types, their characteristics, and ideal applications.

Sewing Machine Needle Chart

| Needle Type | Ideal Use | Characteristics | Key Considerations |

|---|---|---|---|

| Universal Needles | Woven and stable knits, natural, synthetic fabrics | Slightly rounded tip, suitable for various fabrics like cotton, voile, linen, and wool. | Versatile; a go-to needle for a wide range of fabrics. |

| Ball Point Needles | Tightly woven and knit fabrics with a lower stretch factor | Rounded tip for slipping through fibers without cutting, ideal for cotton and polyester knits. | Prevents snags in knit fabrics; suitable for stretch materials. |

| Jersey Needles | Knit fabrics with a medium stretch factor | Rounded tip to prevent laddering or holes in knit fabrics. | Designed to work with knits without causing damage. |

| Stretch Needles | Fabrics with maximum stretch, e.g., dance lycra, spandex | Reduces puckering and skipped stitches in stretch seams. | Ideal for elastic fabrics; ensures smooth and even stitches. |

| Leather Needles | Leather, synthetic suede, faux leather, vinyl | Sharp point for piercing leather, strengthened shaft. Adjust stitch length for optimal results. | Essential for sewing through tough materials like leather. |

| Quilting Needles | Multiple layers of fabric and batting | Strengthened to pierce through layers, ideal for quilting and bag making. | Prevents bending or breaking when sewing through thick layers. |

| Topstitching Needles | Thick thread, multiple layers for topstitching | Large eyes for thick thread, strengthened for sewing through layers. | Ideal for decorative stitching; ensures visibility of topstitching details. |

| Sharps/Microtex Needles | Thin vinyl, applique, silks, tightly woven fabrics | Finer and sharper than universal needles, strengthened for precision sewing. | Suitable for delicate fabrics requiring fine, detailed stitches. |

| Jeans Needles | Sewing denim | Sharp point for piercing thick, dense fabric like denim. | Designed to handle heavy-duty fabrics; suitable for denim and canvas. |

| Double (Twin) Needles | Hems in stretch garments | Two needles joined at the top, designed for stretch fabrics. | Creates parallel rows of stitches; ideal for hems and decorative edges. |

| Machine Embroidery Needles | Computerized embroidery machines | Prevents splitting or shredding of embroidery thread, ensures even stitches. | Specifically designed for dense stitching in machine embroidery. |

| Metallic Needles | Sewing with metallic threads | Extra-large eye to prevent thread splitting, suitable for thicker metallic threads. | Minimizes friction with metallic threads, preventing breakage and shredding. |

Key Considerations:

- Choose needles based on fabric type, thickness, and specific project requirements.

- Ensure needle compatibility with your sewing machine model.

- Use the appropriate needle size for the best results in your sewing endeavors.

How Long Do Sewing Needles Last?

The experienced advice from local sewing experts emphasizes the importance of regularly replacing sewing needles. While manufacturers typically recommend changing needles every 6-8 hours of sewing, some experts suggest doing so even after 8 hours.

Despite the seemingly short lifespan, the affordability of needles makes frequent changes a cost-effective practice, leading to improved sewing outcomes.

Factors Influencing Needle Lifespan

- Usage Time: Manufacturers and sewing professionals agree that after 6-8 hours of sewing, a needle’s performance may decline, impacting the quality of stitches.

- Cost-Effective Maintenance: Though needles are inexpensive, their impact on sewing quality is significant. Frequent replacements contribute to smoother stitching and prevent potential issues.

Table: Lifespan and Replacement Recommendations for Sewing Needles

| Needle Usage Time | Replacement Recommendation | Additional Consideration |

|---|---|---|

| 6-8 hours | Manufacturers’ advice | Standard recommendation for optimal needle quality. |

| 8 hours | Local experts’ suggestion | Extending the replacement timeframe for cost-effectiveness. |

| Accidental pin hit | Immediate replacement | Prevents damage to the needle tip, ensuring consistent performance. |

Key Points:

- Regular needle changes enhance sewing quality.

- Affordability makes frequent replacements a practical choice.

- Immediate replacement is crucial if a needle hits a pin during sewing to avoid tip damage.

Adhering to these guidelines ensures that your sewing machine operates at its best, minimizing potential issues and contributing to a smoother and more efficient sewing experience.

A Step-by-Step Guide on How to Insert a Sewing Machine Needle

Ensuring you correctly insert a sewing machine needle is crucial for the efficiency and success of your sewing projects. Follow these detailed steps to safely and accurately replace your needle:

1. Turn Off the Machine and Remove the Old Needle:

- Ensure your sewing machine is powered off before starting.

- Identify the screw holding the old needle, typically located at the top right. Loosen the screw and carefully pull the old needle down.

2. Examine Your New Needle:

- Observe the top of your new sewing machine needle. Notice that one side is flat, while the other is rounded.

3. Select the Correct Needle Size and Type:

- Choose the appropriate needle size and type for your project.

- Refer to your sewing machine needle chart to ensure the right specifications.

4. Insert the New Needle:

- Insert the new needle with the flat side facing the back of the machine.

- Ensure the rounded side is facing you.

5. Tighten the Screw:

- Securely tighten the screw to hold the needle in place.

- Ensure it is snug, but be cautious not to overtighten, which could cause damage.

6. Double-Check Alignment:

- Confirm that the needle is inserted correctly and aligned according to your machine’s specifications.

7. Power On and Start Sewing:

- Turn on your sewing machine and commence your sewing project with confidence.

Table: Needle Insertion Guide

| Step No. | Action | Additional Tips |

|---|---|---|

| 1 | Turn off the machine and remove the old needle | Ensure power is off for safety. |

| 2 | Examine your new needle | Identify the flat and rounded sides. |

| 3 | Select the correct size and type | Consult your needle chart for guidance. |

| 4 | Insert the new needle | Flat side faces the back, rounded side faces you. |

| 5 | Tighten the screw | Ensure a snug fit without overtightening. |

| 6 | Double-check alignment | Confirm proper needle positioning. |

| 7 | Power on and start sewing | Begin your project with confidence in your needle setup. |

Following these steps and being mindful of needle orientation ensures a seamless needle replacement process, contributing to optimal sewing performance.

Conclusion: Sewing Machine Needle Sizes & Types

In conclusion, mastering the art of sewing machine needle selection is a gateway to elevating your sewing experience. Understanding the nuances of needle sizes, types, and their respective uses empowers you to achieve professional results in every project.

The comprehensive guide and accompanying tables serve as invaluable references, providing insights into the intricacies of needle choices. Whether you’re sewing delicate fabrics or tackling heavyweight materials, the right needle can make all the difference.

With this knowledge at your fingertips, embark on your sewing journey confidently, knowing that your choice of needles will enhance the quality and precision of your creations. Happy sewing!