SINGER 9410 Common Problems and Troubleshooting

Are you in need of a dependable and vintage sewing machine? Look no further than the Singer 9410! Manufactured during the 1940s, this device is an ideal choice for running efficient repairs or crafting beautiful creations. In this article, we’ll explore some of the common issues encountered when using it as well as how to quickly fix them. Plus, we’ll provide advice on optimizing your Singer so that all your projects are hassle-free. Let’s get started now.

Here you can find all the parts and accessories for the SINGER 9410 guaranteed to fit your sewing machine

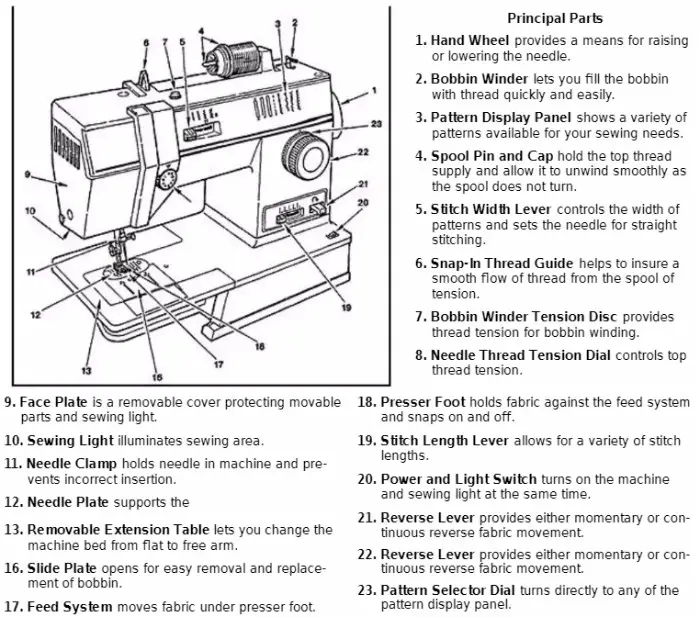

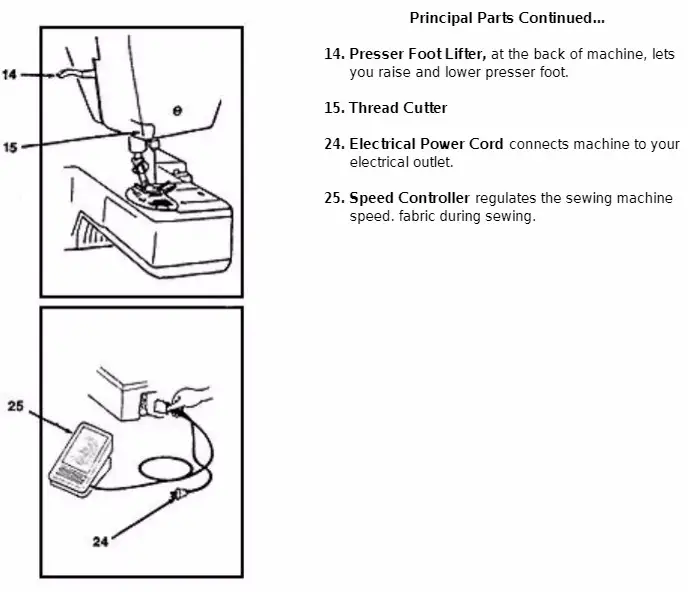

SINGER 9410 Parts Diagram

Understanding your SINGER 9410 sewing machine is a crucial part of stitching success. To get to know all the intricate elements that make it work, consult the owner’s manual and view its page-by-page diagrams. Most sewing machine manufacturers provide basic parts schematics in their manuals for easy reference.

SINGER 9410 sewing machine bobbin tension problems

If you are a SINGER 9410 owner, don’t be alarmed when faced with bobbin tension issues due to misaligned needle plates or incorrectly secured thread. Easy and quick fixes exist that can quickly solve this problem.

Troubleshooting SINGER 9410 bobbin tension problems

To overcome bobbin tension issues on a SINGER 9410, first ensure the bobbin is correctly inserted and your needle plate and feed dog are aligned. Modify the tension dial to ascertain an optimal setting for your project. If these measures don’t provide satisfactory outcomes, consider fitting in a new bobbin case for better results! With this simple checklist of advice at hand, any threading challenges should be quickly conquered.

How to Fix the Bobbin on a Singer 9410?

To fix the bobbin on a Singer 9410, first ensure that the power is off. Unlatch the plate on the side of the machine and lift it up to access the bobbin case. Check that the bobbin is filled correctly with thread and place it in the bottom of the case following the arrows. Push down on top of the case and slide it back into position, then close and latch plate before turning power back on. Test your work by sewing a few stitches to make sure everything is working properly.

Common SINGER 9410 fabric problem

Why is my SINGER 9410 Sewing Machine not moving the fabric? Is your fabric not moving when you use your Sewing Machine? You’re not alone – many people run into similar issues with this machine. If you find yourself stuck and unable to get started, don’t worry! There are plenty of resources available to help guide you through any difficulty that may arise.

Chances are the issue is with thread tension, but don’t fret! When you spend time getting to know your machine and exercise caution when working on projects, nothing will stand in the way of achieving sewing success. So pledge your commitment now and be rewarded later with a flawless finished product each time.

Troubleshooting fabric movement problems on the SINGER 9410

For the best performance of your SINGER 9410 machine, make sure to practice caution. Check that your thread density isn’t too high and each part is threaded correctly per factory instructions. Likewise, tension settings should follow exact specifications for continued peak results.

Take the simple step of carrying out regular maintenance on your Singer sewing machine and you will be rewarded with top results every time. Just follow the instructions in the user manual after each use to ensure all components are properly cleaned or replaced as needed. It is hassle-free, so make sure you don’t forget this important task for optimum performance from your Singer machine.

SINGER 9410 breaking needles

To ensure that your SINGER 9410 needle remains intact and you avoid any unexpected breaks, it is imperative to select the suitable size of needles for every fabric you use, as well as maintain proper thread tensions. Moreover, do not forget to replace all worn out needles frequently so this issue never arises again in future projects. If these steps are followed consistently, breaking of unnecessary needles can be prevented entirely!

Needles that are not the proper type and thread of lesser quality make them prone to snapping. Furthermore, if you stitch too quickly for long periods without any breaks then this might weaken your needles even more. Additionally, lint or dust buildup inside your sewing machine can also be a significant reason why needles do not last as long as they should.

Troubleshooting SINGER 9410 Needle Problems

To ensure maximum performance from your SINGER 9410, be sure to choose the right needle size for each type of fabric and adjust thread tension accordingly. It’s also important that you replace old needles frequently because they won’t work as efficiently after being used a lot.

Additionally, don’t forget to clean out the feed dog area regularly; this will not only prevent any damage but make operation smoother than ever before! Follow these tips closely and any problems should vanish in no time at all.

SINGER 9410 upper thread breaking

Upper thread breakage on the SINGER 9410 Sewing Machine is a common occurrence due to incorrect needle installation, outdated needles, improper tension settings and inadequate bottom thread tensioning.

To guarantee peak performance levels each time you use this machine as well as minimize any damage or harm it may cause, these issues must be handled quickly and prior to using the sewing machine again. By doing this you will also reduce your chance of upper thread breakage in future use.

Troubleshooting SINGER 9410 Upper thread breakage

To ensure maximum efficiency on a SINGER 9410 Sewing Machine and prevent the threads from breaking, start by using the correct needle size and appropriately winding the bobbin. Additionally, double-check any data design system settings if necessary. If threads still break after following these steps, rethread your machine according to instructions and make sure both upper thread tension levels are adjusted accordingly.

In addition to this routine maintenance process, use an appropriate 80% filled bobbin for stitching projects; always keep fabric taut when in use too! Finally – before replacing with new string – remove any knots or tangles present in used thread first. All of these precautions should ultimately resolve all issues related to broken upper threads problems once taken into consideration.

SINGER 9410 Keep Jamming

If your SINGER 9410 sewing machine is jamming, there may be a few sources of the issue. Tangled thread and uneven fabric feeding can definitely cause it to malfunction, but lint or dust build-up as well as something inside the needle hitting are both possibilities. Always take precaution when using this device so you don’t run into further problems.

Troubleshooting Jamming Problems on the SINGER 9410

To avoid jamming in the SINGER Model 9410, regularly clean the lint trap and wipe down the exterior with a soft cloth. Additionally, oil any moving parts as necessary per the instructions in the user manual. Following these steps will help keep your machine running smoothly.

Here you can find all the parts and accessories for the SINGER 9410 guaranteed to fit your sewing machine

Common SINGER 9410 bobbin thread problems

In order to guarantee your SINGER 9410 sewing machine runs optimally, you must be conscientious of its maintenance and care. Otherwise, issues such as the bobbin thread tangling or breaking frequently, skipped stitches, uneven stitching and seams unravelling once finished can all arise. Prevent these mishaps by taking proper action now.

Troubleshooting SINGER 9410 bobbin thread problems

To avoid problems with the SINGER 9410 bobbin thread, use the correct type of bobbin, make sure there is enough thread but don’t overfill it, insert the bobbin case correctly and replace worn tails with longer ones. Additionally, adjust or regulate the tension settings accurately for successful results.

SINGER 9410 bobbin holder problems

Are you finding that your SINGER 9410 Sewing Machine Bobbin Holder is coming out of place? Don’t worry – it’s typically due to either dirt build up or the wrong model being used. Fortunately, both of these can be easily remedied with some troubleshooting and you’ll have a running machine again.

Troubleshooting SINGER 9410 bobbin holder problems

If you’re experiencing difficulty with your SINGER 9410 bobbin holder, first make sure that the finger is correctly placed on the needle plate and lightly press it down using a pencil eraser. Then use a cotton swab to clean out any dust or debris inside of the case latch, followed by blowing compressed air into it to remove any remaining residue.

To prevent further issues due to incompatibility or dirt build up in future, only utilize bobbins specifically designed for this model. Remember: regular maintenance can save you from future frustrations.

Common SINGER 9410 bobbin winding problems. Bobbin winder not spinning

Encountering difficulty winding your SINGER 9410 bobbin? It is likely due to a worn-out tread, which can be caused by excessive usage or simply the passage of time. To confirm this suspicion, inspect the spool wheel thoroughly for any evidence of fractures and alterations in shape.

Troubleshooting Bobbin winder problems on the SINGER 9410

In the event that your SINGER 9410 experiences issues winding bobbins, there are a few possible solutions. Replacing any worn tires and adjusting its winder assembly should do the trick. If not, then you might have to replace either the power switch or motor; while doing so it would be wise to inspect all other sewing machine components for any signs of wear or damage. A little preventive maintenance will undoubtedly help keep this device in perfect working order.

SINGER 9410 Sewing Machine Tension Problems

With its effortless design, the SINGER 9410 is generally straightforward to use. However, on rare occasions issues such as bunched upper threading may surface due to an overly tightened bobbin case or misguidance. To guarantee a hassle-free sewing experience and prevent any tension problems from arising, it’s essential that you address them right away.

Troubleshooting tension problems on the SINGER 9410

Achieving great results with the SINGER 9410 is easy if you follow these steps to troubleshoot tension problems. Ensure the needle is threaded correctly, and then wind bobbin thread evenly. Tension discs should also be carefully aligned and adjusted to suit your fabric type while using a suitable size of needle. Doing this will help eliminate any tension issues that may occur, allowing you to create beautiful projects with ease.

Common SINGER 9410 stitch problems

The SINGER 9410 Machine is renowned for its endurance and stability, thrilling craftspeople around the world. Even if adjusting stitch length or utilizing zigzag functions appear complex at first glance, with a few basics and advice you will soon know how to use them correctly. Any loose or tight stitching issues can be quickly remedied as well.

Troubleshooting SINGER 9410 stitching problems

To make the most of your SINGER 9410, it is critical that you adjust all settings to match each project and select needles suitable for every fabric. Additionally, be sure to keep up with maintenance tasks like clearing out lint from the feed dog area and replacing worn-out needles. With careful customization, a focus on upkeep and some troubleshooting skills in place, you can ensure maximal success with this sewing machine.

SINGER 9410 Sewing machine parts

The SINGER 9410 may experience problems with parts and components due to normal wear and tear, improper use, or age. If any of these problems arise, it is important to identify the cause of the issue quickly, in order to prevent further damage to your machine.

For more information about the most common problems with parts and components of the sewing machine SINGER 9410, as well as the causes of these problems and how to fix them, read our other article.

For this SINGER model, we’ve identified the most common parts issues and created dedicated articles to help you resolve them.

SINGER 9410 Sewing machine presser foot problems

For more information about the most common problems with presser foots of the SINGER 9410, as well as the causes of these problems and how to fix them read in this article of ours.

SINGER 9410 Sewing machine motor problems

For more information about the most common problems with machine motor of the SINGER 9410, as well as the causes of these problems and how to fix them read in this article of ours.

SINGER 9410 Sewing machine belt problems

For more information about the most common problems with belt of the SINGER 9410, as well as the causes of these problems and how to fix them read in this article of ours.

SINGER 9410 Sewing machine thread cutter problems

For more information about the most common problems with thread cutter of the SINGER 9410, as well as the causes of these problems and how to fix them read in this article of ours.

Hand wheel problems on SINGER 9410 sewing machine

For more information about the most common problems with hand wheel of the SINGER 9410, as well as the causes of these problems and how to fix them read in this article of ours.

Here you can find all the parts and accessories for the SINGER 9410 guaranteed to fit your sewing machine

SINGER 9410 Manual

The instruction manual for the SINGER 9410 sewing machine can be found here.

FAQ

Why does my sewing machine keep jamming underneath?

Have you been wondering why the fabric keeps getting jammed underneath your sewing machine? This can be due to several issues, including a tangled thread or uneven feeding of the fabric. Additionally, lint and dust build-up in the machine may also cause jams as well as when something is hit by the needle while sewing. Therefore, always keep an eye on where that needle is going!

What Size Bobbin for Singer 9410?

The Singer 9410 is designed to use Metal Bobbins Class 66. For confirmation that either variation can be used with this specific model, please refer to the owner’s manual.

How do I reset the bobbin tension?

If the bobbin case doesn’t move, it’s because your tension is too tight. To make sure you’re setting it correctly, turn the tiny screw on the bobbin case clockwise for a tighter hold or counterclockwise to loosen. It only takes a minor adjustment of no more than one-fourth of a turn!

What year was Singer 9410 made?

The Singer 9410 was made in the 40s. It was originally released as a compact, portable sewing machine that could be easily stored away when not in use. With its lightweight design and easy portability, the Singer 9410 was an ideal choice for those looking to bring their sewing projects on the go! However, despite its convenience, this model is no longer produced today due to age and the availability of newer models on.

Conclusion. SINGER 9410 Common Problems and Troubleshooting

With proper maintenance and use, you can keep your Singer 9410 Sewing Machine running for a long time. Knowing the most common problems associated with this device can help you prepare for any potential difficulties that may arise while using it. With this information in hand, you will be able to get the most out of your sewing machine and continue creating beautiful garments and apparel.