SINGER M1505 sewing machine bobbin tension problems

Having trouble with the bobbin tension on your SINGER M1505 sewing machine? Don’t worry – it’s a common issue that can be easily fixed! To get the perfect bobbin tension, you must first identify what the problem is and make adjustments accordingly. Once you’ve done this, you’ll be able to diagnose any future bobbin issues and ensure that each stitch looks amazing! So don’t give up hope – read on for more advice about how to fix your bobbin tension problems.

What is the SINGER M1505 sewing machine bobbin tension?

The amount of tension in the thread determines how tight or loose your stitches are. If there is too much tension, the threads will be pulled apart and might even break. Conversely, inadequate tension causes sagging and excess slack that cannot lay flat on fabric.

The Singer M1505 sewing machine bobbin tension can be adjusted by using a small screw to regulate the amount of pressure on the thread. Tightening this screw increases the tension, while loosening it reduces it and can prevent threads from breaking or sagging unevenly when stitching fabric. Proper adjustment of this tension is essential for successful projects.

What does good SINGER M1505 sewing machine bobbin tension look like?

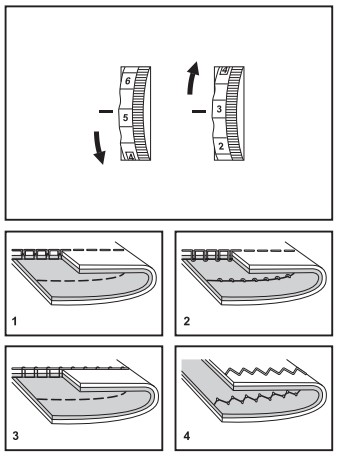

The thread tension between the upper and bobbin threads plays an important role in forming good quality stitches. When stitched correctly, these two should come together seamlessly at the center of your fabric while safely intertwining with one another – no exceptions! From the top side of your project, you won’t be able to see any sign of that lower thread in action; similarly, as you flip it over there will be no trace left from that upper thread either.

If your bobbin tension is slightly off, it will become evident in the way the two threads are stitched together. You can easily spot this by simply examining a section of stitching that looks suspicious – for instance, if you find the lower thread popping through to the top or upper thread becoming loose. To prevent any future issues with fabric on your next project, make sure to check and adjust bobbin tension beforehand!

Lower thread tension

The tension on the Singer M1505 sewing machine bobbin has already been set at the factory, so no adjustment is necessary. It’s important to remember that a balanced tension (where both top and bottom threads are equal) is only optimal for straight stitching. For zig zag and decorative sewing stitch functions, thread tension should generally be less than for straight stitch sewing. Overall, 90% of sewing projects will require a tension between 3 and 5.

What does good bobbin tension look like?

To determine if your tension levels are correct, slide the bobbin into its case. Lift it up with only the thread and see whether or not it stays in place; this is an indication that you have achieved accurate tension. If pulling on the thread lightly causes a slight downward motion of your casing, then you can be sure that you’ve found balance! On the other hand, if one hard tug allows for easy dropping of your casing -then unfortunately it’s too loose.

SINGER M1505 sewing machine bobbin tension problems

Have you ever wondered what bobbin tension is? What is the bobbin tension? Bobbin tension applies pressure to the thread in a bobbin case, generated by two pieces that are held together with a tiny screw. When this screw tightens, so does the pressure; when it loosens, this causes the opposite effect. The metal plate/spring assembly remains set at an exact tension during production and constantly maintains steady thread tensions as your sewing project evolves.

How Do You Adjust The Bobbin Tension On A SINGER M1505 Sewing Machine?

- If you wish to adjust the bobbin tension on your SINGER M1505 Sewing Machine, please make sure to look through the manual of your particular model. This is vital in order for you to familiarize yourself with any applicable instructions and guidelines before carrying out this adjustment;

- Test the strength of your stitching by sewing a seam on folded fabric, then tugging gently to see if it will break;

- If your machine is only displaying one broken thread, attempt to correct the bobbin tension first;

- To gain access to the bobbin area of your sewing machine, detach its faceplate;

- Remove the bobbin and its case via the hinged latch but keep the bobbin in the case;

- Use a screwdriver that fits the size of the screw on the side of your bobbin case, and turn it to adjust accordingly;

- Resist the temptation to exert too much force; instead, make small adjustments to tighten the screw;

- To increase the bobbin tension, turn the knob clockwise; to decrease it, rotate counterclockwise;

- Tension can be gauged by pulling lightly on the bobbin thread to feel its resistance;

- When the thread easy to pull out, it’s a clear indication that the tension is too loose;

- When the thread won’t come out, it usually means that the tension is too tight on your sewing machine;

- Reinstall the bobbin in the SINGER M1505 sewing machine;

- Reattach the faceplate for added security;

- To ensure that your seam is properly sewn, stitch diagonally on the fabric as instructed in step 2;

- The top and bottom of your stitches should be even, with the center securely locked in place;

- Ensure that each thread remains intact when tugged on to guarantee fabric longevity.

When to adjust the bobbin tension on a SINGER M1505 Sewing Machine?

To ensure your sewing machine is working correctly, it’s best to adjust the top thread tension first before making any changes to the bobbin tension. However, if you’re using a very fine or thick thread, you may need to adjust the bobbin tension accordingly.

Make sure to only turn the screw in minor increments and test after each movement so that you can achieve optimal results. Also be aware that manufacturers have already set the bobbin tension for most projects, so use this as your starting point.

What tips can you give for troubleshooting bobbin problems?

• Make sure the spool of thread is placed correctly on your machine. Check that the thread is moving freely and not caught between any parts.

• Check if the bobbin case is inserted properly in the machine – it should be flush with the machine body when inserted.

• Clean out any dust or lint from inside the bobbin case, as well as from behind the needle plate of your machine.

• The tension disk/spring should be located at a 45 degree angle to ensure optimal tension on your thread. If it isn’t, adjust it until it is so you can get better stitch quality.

– Use high quality thread and needles for smooth, even stitching.

– Don’t forget to oil your machine regularly – this will help keep it running smoothly for a longer period of time.

– Finally, make sure the bobbin winder is loosened before you start sewing, otherwise it can cause problems with the tension on the thread.

Following these tips will help you troubleshoot any bobbin problems you may be having with your SINGER M1505 sewing machine. Good luck!

How do you fix the bobbin tension on a SINGER M1505 sewing machine?

Battling bobbin tension issues while working on the SINGER M1505 sewing machine? Don’t let it get you down! How do I reset the bobbin tension? Resetting the bobbin is easier than ever. All that’s necessary is to remove the faceplate of your machine, take out its case and bobbin using a hinged latch, and then you’re ready to go. Quickly address any problems with this straightforward method so that you can keep enjoying seamless stitching performance!

Next, take out a screwdriver and carefully turn the screw that’s on the side of the bobbin case. Rotate it clockwise to increase tension or counterclockwise for decreased tension, then test its effectiveness by tugging gently on your bobbin thread.

Once this is adjusted correctly and the faceplate is secured again, test a seam by sewing on the diagonal of fabric and ensure that the stitches look even on both sides with no single thread breaking when pulled. With this method, you be able to troubleshoot bobbin tension issues and get your SINGER M1505 sewing machine back up and running.

SINGER M1505 sewing machine Thread bobbin Tension Test

To get a better understanding of the tension settings on your SINGER M1505 sewing machine, it’s essential to sew with two different colored threads. This allows you to observe if there are any imbalances in bobbin tension more easily and accurately. You can also use the same thread but make sure that enough stitches have been sewn so that you can properly evaluate the outcome.

Additionally, it is important to sew your test stitches on the same type of fabric that you will be using for your project so you don’t have to adjust the tension again when beginning work on it.

FAQ

What happens if bobbin tension is too loose?

If your bobbin thread isn’t forming the correct stitches with the top thread, it could cause fabric puckering, tension build-up and broken threads. Not to mention, improper stitching lines. All of these issues can be avoided by ensuring that your bobbin thread is properly adjusted in relation to the upper thread.

What happens if the bobbin tension is too high?

When your tension is set too tight, the thread may be pulled through to the top of your fabric. Additionally, it can cause an odd stitch and create bunching throughout the material. To remedy this issue remember that “lower” and “loosen” both begin with ‘L’. Simply lower your number on the dial to achieve a more relaxed tension!

What Tension Should Your SINGER M1505 Sewing Machine Be On?

Sewing machines typically possess tension dials ranging from 0 to 9. For the majority of regular tasks and conventional stitches, your machine’s tension should ideally stand at 4.5 – a setting that may not be obtainable on every machine. Nonetheless, 3, 4 or 5 will do nearly as well for most projects you have in mind!

Why SINGER M1505 Sewing Machine Bobbin thread showing on top?

If you are seeing loops of the bobbin thread on the right side of your fabric, this indicates that the tension for the bobbin thread is too loose. To fix this, reduce the tension of your needle thread by adjusting the dial to a lower number. This should help correct any issues with visibility of your bobbin thread.

When to adjust the bobbin tension?

When sewing, the bobbin thread tension should be adjusted depending on the fabric thickness, stiffness, number of layers being sewn, and type of stitches/techniques being used. Bobbin tension also needs to be adjusted when using different thread weights, a twin needle, elastic thread (e.g. for shirring), and when doing stippling or free motion quilting. If problems with skipped stitches occur due to breaking threads in the bobbin despite adjusting only the upper thread tension, bobbin tension should also be changed accordingly.

Conclusion

In conclusion, bobbin tension issues on SINGER M1505 sewing machines can be a common problem. However, by following the right steps and using the necessary tools, it is possible to easily adjust the tension and get the machine back in working order. With the proper setup, you will have a reliable sewing machine that can provide successful projects with ease. Ultimately, learning how to properly adjust the tension on SINGER M1505 is an important part of becoming a confident and experienced sewer!