Sewing machine SINGER M1505 bobbin winding problems

If your SINGER M1505 sewing machine bobbin isn’t winding or has suddenly stopped, it’s understandable that you would ask yourself “Why is my bobbin not spinning? Why won’t the winder spin?” It can be frustrating trying to figure out what might be wrong.

Sewing machine SINGER M1505 bobbin winding troubleshooting

Don’t fret if your SINGER M1505 sewing machine’s bobbin winder isn’t working – this issue is more widespread than you think! Thankfully, there are several potential causes of why it might not be functioning correctly.

SINGER M1505 sewing machine Bobbin winder not spinning

“How do I fix my bobbin winder?” If your bobbin won’t wind, to resolve this issue, please follow the steps listed below.

1. Ensure that the correct size bobbin is being used in the Bobbin Winder: If you are using a bobbin that is too big or too small, it can prevent the Bobbin Winder from spinning. Make sure you use a bobbin that fits snugly and securely into the winding mechanism.

2. Ensure that the groove on the bobbin is aligned with the spring located on the Bobbin Winder shaft. To do this, press down on the Bobbin until it clicks into place. This will help guarantee that your thread is wound onto the bobbin properly.

3. Ensure that the thread is routed properly through the bobbin winding guide. With the needle in its highest position, pass the thread from left to right through the slot at the rear of the sewing machine. This will facilitate smooth bobbin winding.

4. It is important to inspect your bobbin for any scratches or signs of wear. If there are any visible marks, it’s necessary to replace the bobbin as soon as possible in order to prevent any issues while sewing with a SINGER M1505 sewing machine. Failing to do so could lead to bobbin winder not spinning correctly and cause other problems.

5. To use the bobbin winder on a SINGER M1505 sewing machine, the lever must be pushed towards you. This will be indicated by a red light that should turn on to confirm that the winder has been engaged and is ready for use.

6. If the thread has been wound overly tight around the bobbin, it may be difficult to remove from the winder. To loosen it, one can utilize tweezers or their finger and manually uncoil the thread.

7. Examine underneath the small bobbin pin using a mini flashlight. If there is thread wound around the bobbin holder’s pin, it may be preventing the winder from spinning. Carefully use tweezers to unwind and remove this thread, taking care not to let it drop into the SINGER M1505 sewing machine itself.

We suggest examining the bobbin pin thoroughly to ensure whatever material is causing your machine’s winder to stop spinning is completely removed before you attempt any further action. Doing so will help keep your SINGER M1505 sewing machine running smoothly.

8. Check for any possible obstructions in the thread path that could be inhibiting the bobbin winder from spinning. If there are any threads or other objects blocking or interfering with how your thread is winding onto the bobbin, this will need to be removed before use.

9. Verify that all components of the SINGER M1505 sewing machine are firmly in place, and check for any broken or loose springs. Replace any worn out springs as necessary to ensure proper operation of the bobbin winding mechanism. Be sure all screws, pins, and other parts are securely fastened.

10. Regularly maintaining and lubricating your SINGER M1505 sewing machine will help to avoid issues with bobbin winding. Make sure that you clean your SINGER M1505 sewing machine from time to time and add the appropriate oil or grease as needed for friction-free performance.

11. Ensure that your tension is adjusted at the right level for the fabric type you plan to sew. If it’s set too high or low, it can cause problems with bobbin winding on a SINGER M1505 sewing machine. Refer to the SINGER M1505 sewing machine manual for an accurate number reading of how much tension should be used.

12. Ensure that the quality of thread used is good and free from knots or tangles, as this may prevent it from winding properly onto the bobbin, resulting in bobbin winding problems.

13. If all of the troubleshooting methods mentioned above fail to resolve the bobbin winding issue on your SINGER M1505 sewing machine, it could be necessary to bring it in to an experienced professional for a thorough examination.

This will help identify any underlying problems and get your SINGER M1505 sewing machine back up and running as quickly as possible. It is important to make sure that only qualified technicians are allowed to work on your machine in order to ensure quality repairs and prevent future issues.

By following these steps, you should be able to rectify your SINGER M1505 sewing machine bobbin winding issues.

SINGER M1505 sewing machine winding instructions

How to wind a bobbin sewing machine SINGER M1505? Follow these straightforward steps! Don’t forget, you must always wind the bobbin before threading your sewing machine and needle for optimal results.

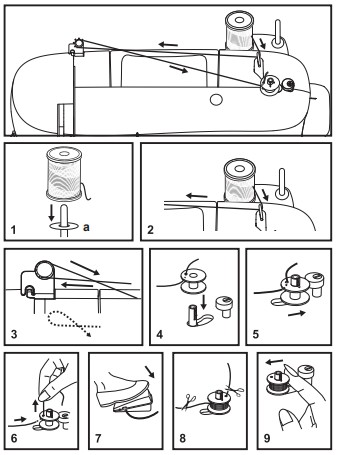

- Place the thread and spool pin felt (a) onto the spool pin. (1)

- Draw the thread from the spool through the upper thread guide. (2)

- Wind the thread clockwise around bobbin winder tension discs. (3)

- Thread bobbin as illustrated and place on spindle. (4)

- Push bobbin spindle to right. (5) – Hold thread end. (6)

- Step on foot control pedal. (7)

- Release the pedal after a few turns. Release the thread and cut as close as possible to the spool. Press the pedal again. Once the spool is full, it rotates slowly. Release the pedal and cut thread. (8)

- Push bobbin spindle to left (9) and remove.

Please Note: When the bobbin winder spindle is in “bobbin winding” position, the machine will not sew and the hand wheel will not turn. To start sewing, push the bobbin winder spindle to the left (sewing position).

SINGER M1505 sewing machine sews when winding the bobbin

For those new to sewing, a common issue that may arise when using the SINGER M1505 machine is having your needle sew during bobbin winding. To guarantee uninterrupted operation and avoid this incident altogether, press the bobbin winder pin towards the right so as to stop your needle’s motion.

Uneven bobbin winding on sewing machine SINGER M1505

Sewing with the SINGER M1505 machine can be a frustrating experience if your bobbin is improperly wound – due to unevenness, looseness or crisscross thread. This not only results in tension imbalance and unappealing stitch work, but it may even lead to broken threads and jamming! Avoid these troubles by ensuring that your bobbins are correctly wound.

Why Is My Bobbin Not Winding Evenly?

- Ensure that the thread is stretched tightly and properly looped around all tension discs;

- Guiding the thread in an up-and-down motion as it winds ensures proper winding;

- Confirm that your bobbin winder is engaged correctly;

- Bobbin winder not fully engaged;

- Use only SINGER M1505 sewing machine model compatible bobbins for best results;

- If you suspect broken or defective metal or plastic bobbins, replace them promptly ;

- Inspect rubber ring on bobbin winder to make sure there are no signs of wear and tear from usage over time;

- Observe if any gears broken the Bobbin Winding Mechanism appear malfunctional.

Adjusting uneven bobbin winding on sewing machine SINGER M1505

To adjust an uneven bobbin winding on your SINGER M1505 sewing machine, begin by checking the bobbin winding pin for any thread hindrances and remove them with tweezers if necessary. Then wrap the thread twice around tension discs before guiding it up and down as it winds or use a finger/pencil to help guide.

Fully engage the bobbin winder, ensure you are using the correct size of bobbins (metal or plastic) and replace any defective ones, replace worn rubber rings at bottom of bobbin winding pins, inspect gears inside of mechanism for repairs -or buy- if broken.

SINGER M1505 sewing machine has exclamation point when winding bobbin

SINGER M1505 sewing machines may experience a jam when winding bobbins, resulting in an exclamation point showing up. This is likely due to something jamming up in the machine, such as a motor belt, bobbin or gears. To remedy this, unplug the machine and clean it first. Then spin the machine forward and backward to check for any parts that might be stuck. If any of the nylon gears are damaged, this could impede operation, causing the machine to get stuck.

SINGER M1505 sewing machine doesn’t re-engage after winding bobbin

SINGER M1505 sewing machines can experience problems if the bobbin winder is engaged. If there is a knot or snag in the upper thread or bobbin thread, it can jam up the machine. To prevent this, ensure that nothing is blocking the hook of the bobbin case and keep your SINGER M1505 sewing machine clean. Additionally, use high-quality standard thread when winding bobbins to avoid creating knots.

SINGER M1505 sewing machine beeping when winding a bobbin

The SINGER M1505 sewing machine is equipped with an audible beeping system that alerts you when a bobbin winding problem arises. This can often result from incorrect threading, obstructions of the tension discs which impede the upper thread’s ability to move freely or perhaps due to issues with the bobbin case itself not allowing it to rotate properly.

It is not uncommon for SINGER M1505 sewing machine to have chips or burrs on the bobbin case, and fortunately, it’s inexpensive to replace. Moreover, you must also ensure that the bobbin winding spindle has been pushed back into its original position on the left side; otherwise your machine will make a racket while attempting to sew.

Motor jammed on SINGER M1505 sewing machine after winding bobbin

Fix a jammed SINGER M1505 sewing machine after winding bobbin. If your sewing machine is stuck, it can be very frustrating. Thankfully, there are some steps you can take to try and fix the problem at home before taking it to a shop.

A great way to start troubleshooting your issue is by clearing the sewing area of any fabric and threads. Turn the wheel manually and check if you can lift up the needle, as a broken one could be causing this problem. Additionally, make sure that there is no lint or thread around the bobbin case – use a stiff brush for debris removal in those hard-to-reach areas. Finally, unscrew the plate at bottom of sewing area to further examine it for possible causes of error.

How do you troubleshoot a bobbin problem?

In this video, sewing machine manufacturer Singer explains how to troubleshoot bobbin problems:

How to load a SINGER M1505 sewing machine bobbin

To learn how to thread a bobbin on a SINGER M1505 sewing machine, watch this video:

Inserting the SINGER M1505 sewing machine Bobbin

Before inserting or removing the bobbin, be sure that the needle is in its highest position.

- Swing open the hinged lid for access (1)

- Gently tug the bobbin case tab (a) to remove the bobbin case (2)

- Grasp the bobbin case with one hand and place the bobbin in it with its thread running clockwise (as indicated by an arrow) (3)

- After inserting the thread through the slit, gently guide it underneath your finger. Make sure to leave a tail of six inches for future use(4)

- With one hand, firmly grasp the hinged latch of the bobbin case (5)

- Securely place it inside the shuttle (6)

Warning: Prior to inserting or removing the bobbin, make sure that the power switch is set at “O” (off).

Bobbin size for SINGER M1505 sewing machine

The SINGER M1505 sewing machine uses the Singer Class 15 Transparent bobbins

Bobbin size chart

FAQ

Can bobbin winder be oiled?

Should be done if the bobbin winder does not spin? If your bobbin winder isn’t spinning, first check to make sure there is nothing blocking it. Secure the bobbin winder back into its mount with four screws and add a drop of oil into the port in the bushing to improve rotation. With these steps, you will be on your way towards repairing this issue quickly!

What is the best way to wind a bobbin?

To wind a bobbin, begin by attaching the spool of thread onto the spool pin and securing it with its holder or cap. Draw the end of your thread through the small hole on its rim before pushing your bobbin’s winder pin to the right while holding down that same piece of thread. Step on your machine’s speed controller until you have enough wrapped around; then release both items and cut away any excess threads for an optimal finish.

How do you adjust the tension on a bobbin winder? How do I know if I have set up my tension correctly?

To find out if you have set up the tension correctly, refer to your machine’s manual and look for the number indicated for the type of fabric you are using. If it is too high or too low, it may cause issues with bobbin winding.

How often should I clean and lubricate my SINGER M1505 sewing machine?

It is recommended to clean and lubricate your SINGER M1505 sewing machine regularly in order to keep it running smoothly and efficiently, avoiding potential problems with bobbin winding.

What should I do if no amount of troubleshooting seems to fix my bobbin winding issue?

If troubleshooting does not seem to fix your SINGER M1505 sewing machine Bobbin Windingcerns, it might be time to take your machine into a professional repair shop for a check-up. This will help to ensure that any underlying problems are correctly identified and fixed.

Can I use any type of thread for bobbin winding?

It is best to use good quality thread when winding bobbins as lower quality threads may cause issues with the bobbin winding process. Avoid using threads that have knots or tangles as these can affect how it winds onto the bobbin and lead to further issues. SINGER M1505 sewing machine Bobbin Winding is easy to do with the right steps and tools. With regular cleaning and maintenance, it is less likely for you to experience problems with bobbin winding. If any underlying issues are present however, contact a professional repair shop for assistance.

Conclusion. How do you fix a SINGER M1505 sewing machine that won’t wind a bobbin?

In conclusion, winding a bobbin on the SINGER M1505 sewing machine is not difficult as long as you follow the correct steps. It is important to use good quality thread and also to maintain your machine regularly with cleaning and lubrication in order to avoid any problems related to bobbin winding.

If troubleshooting fails to fix the issue, it is best to contact a professional repair shop in order to identify any underlying problems. With proper maintenance and care, you should be able to enjoy successful bobbin winding with your SINGER M1505 sewing machine.