SINGER M1605 Sewing machine breaking needles

Sewing is a great way to express creativity and make beautiful clothes and items for the home. However, using the wrong needle in the SINGER M1605 sewing machine can cause needles to break, resulting in serious problems. In this article, we’ll discuss how to prevent needle breakage on the SINGER M1605 sewing machine and achieve optimal results.

Why break needles on the sewing machine SINGER M1605?

Don’t just switch out your SINGER M1605 needle when it keeps snapping – take the time to identify the underlying cause. You have a few options for repair before throwing in the towel, so don’t lose hope! If you notice any sign of damage on the needle itself, make sure you get a new one right away so that future stitching projects are not disrupted.

Common Problems Causing A Needle Break in Sewing Machine SINGER M1605

The SINGER M1605 sewing machine can be affected by five possible malfunctions that could result in a broken needle:

- The needle on sewing machine SINGER M1605 is damaged, bent

- The needle on sewing machine SINGER M1605 is Dull

- Incorrect needle size for fabric

- Wrong SINGER M1605 sewing machine thread tension

- The wrong SINGER M1605 sewing machine presser foot is attached

Understanding the various issues that can lead to needle breakage in a SINGER M1605 sewing machine is essential. Let’s take a look at some of the most common culprits:

The needle on sewing machine SINGER M1605 is damaged, bent

Before commencing your project with a SINGER M1605 sewing machine, be sure to inspect the needle for any signs of wear or damage. If you discover that it is indeed damaged, replace it with a sharper one – this is particularly important when working on thicker fabrics as an old/bent needle can fracture while stitching due to the strain. Additionally, slower stitching speeds will also help preserve the equipment from potential harm during use.

The needle on sewing machine SINGER M1605 is Dull

To create stunning and long-lasting pieces, it’s essential you replace the needle of your SINGER M1605 sewing machine every 8-10 hours of use. This will help minimize any damage or skipped stitches while guaranteeing a professional finish on all fabric items crafted. If at any point there is wear visible on the needle, make sure to change it right away! With this attention to detail, you can look forward to crafting beautiful projects that stand out for years to come.

For the greatest performance and longevity of your SINGER M1605 sewing machine, it is essential to regularly inspect the needle. To confirm whether or not it has dulled, take a pocket knife blade and scrape against it; if there’s any friction or resistance detected then replace immediately for optimal use.

How to check the needle on a SINGER M1605 sewing machine

It’s essential to always check the needle of your SINGER M1605 sewing machine before you start working. Put it on a level surface and make sure both sides are evenly distributed. If there is any warping or bending, don’t use that needle! This precaution will guarantee optimal performance from your sewing equipment and avoid future issues.

In order to maintain the utmost safety while operating a home sewing machine, it is essential to use needles that have been specially designed for this purpose. If an outdated or broken tool is used, there could be potentially hazardous consequences for both you and those around you! By adhering to this practice, not only will your performance reach its full potential – but everyone’s safety will also remain intact.

(1) Flat side (2) Needle type marking

– Correct needle

(3) Parallel space (4) Flat surface

– Incorrect needle

If the needle is not even with the flat surface, it is bent. Do not use a bent needle.

(5) Flat surface

Incorrect needle size for fabric

When you begin a sewing project, the size of needle that you select is critical in order to prevent breakage and preserve the aesthetic integrity of your piece. By prioritizing proper selection according to fabric type and thread thickness–as outlined in Singer M1605 manual–you can guarantee that both projects retain their desired allure while needles are kept safe from excessive strain!

Needle and thread combinations

Need a needle for your SINGER M1605 sewing machine? Look no further than the helpful chart provided! With it, you can easily select the perfect combination of thread, fabric and needles to ensure flawless results every time. Don’t compromise – get tailor-made perfection from your fabrics today!

To sew with excellence, it is essential to match the correct needle size with the appropriate thread and fabric weight.

Important to know:

- Forging an improper combination like thick fabric such as denim with a small needle (e.g., 65/9 – 75/11) can be hazardous and cause potential harm, since the needle may break or bend when sewing. Additionally, it could yield irregular stitches that do not look uniform at all.

- Avoid using thread of weight 20 or below at all costs as it can result in an array of undesirable problems.

- For a secure and smooth stitch, choose a ball point needle (golden-hued) when working on stretch fabrics or materials that tend to overlook stitches.

- No matter what your fabric and thread type are, a needle size of 90/14 to 100/16 is the perfect choice when using transparent nylon thread.

- The lesser the thread number, the stronger its structure; and correspondingly, a larger needle number indicates thicker needles.

Wrong SINGER M1605 sewing machine thread tension

Thread tension is an imperative aspect of sewing that helps avoid needle breakage. It should be altered according to the weight and type of fabric being used, as well as both upper and lower thread weights must be equal in order to provide precise tensioning so needles won’t bend or snap. Getting satisfactory outcomes with your SINGER M1605 sewing machine can easily be attained by following these steps!

The wrong SINGER M1605 sewing machine presser foot is attached

If you don’t use the correct type of presser foot with a SINGER M1605 sewing machine, needles may become damaged due to repeated strikes against them. Taking precautionary steps like selecting the appropriate foot for each pattern and confirming that settings are correctly adjusted is paramount in avoiding needle damage while achieving excellent results.

How to set the presser foot on the SINGER M1605 sewing machine

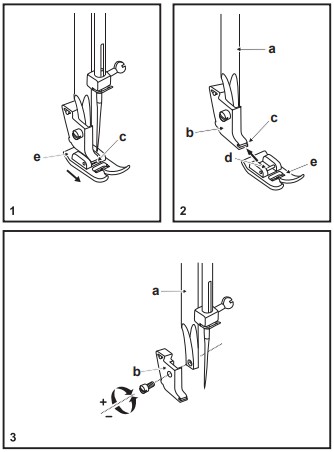

To remove the presser foot, push it (e) away from its slot (c). For attachment, insert the pin of the foot into its holder. To unclip and attach a shank: raise the bar (a), then affix or detach as shown in Figure 2.

IMPORTANT: Don’t forget to switch off (“O”) your device when completing any of these tasks!

Conclusion

To ensure you achieve flawless results with your SINGER M1605 sewing machine, make sure to choose the right needle size for the fabric and thread type being used. Additionally, don’t forget to adjust the thread tension as needed and attach an appropriate presser foot. By following these simple tips, you can guarantee peak performance from your beloved SINGER M1605 sewing machine! With proper care and maintenance, it will provide years of dependable use – so no more worries about costly repairs or replacements in sight.