Singer Quantum Stylist 9960 Common Problems and Troubleshooting

Are you having trouble with your Singer Quantum Stylist 9960 sewing machine? It can be frustrating not being able to complete a project. But don’t worry, we’re here to help! In this article, we will discuss some of the common problems associated with the Singer Quantum Stylist 9960 model and provide step-by-step solutions for each.

We’ll also offer useful advice on how to prevent future issues from occurring. With our guidance, you can quickly get your sewing machine running properly again in no time! Read on to find out more about troubleshooting your Singer Quantum Stylist 9960 today!

Here you can find all the parts and accessories for the Singer Quantum Stylist 9960 guaranteed to fit your sewing machine

Common Singer Quantum Stylist 9960 stitch problems

The Singer Quantum Stylist 9960 is an excellent choice for sewing enthusiasts, as it provides both efficiency and dependability. Occasionally there can be issues with stitches like the zigzag feature not working or stitching being too tight/loose, but these can easily be fixed with the proper equipment and techniques. Additionally, common problems such as skipped stitches or difficulty changing stitch length settings are totally normal and quickly repairable.

Troubleshooting Singer Quantum Stylist 9960 stitching problems

When using the Singer Quantum Stylist 9960 sewing machine, it is important to be mindful of potential stitching issues that could arise such as loose stitches, incorrect stitch length, skipped stitches, and zigzag malfunctions. These issues are usually caused by incorrect thread tension, wrong needle size or lint build-up.

To fix these errors one must readjust the settings on both upper and lower threads and ensure they are using the right needle size according to their fabric type. Furthermore, cleaning any lint accumulation in the feed dog area and replacing old needles with new ones suitable for the fabric type can help avoid stitch problems in the future.

Doing regular maintenance and troubleshooting should assist in preventing many common stitching issues from occurring.

Singer Quantum Stylist 9960 Sewing Machine Skipping Stitches

Skipped stitches on the Singer Quantum Stylist 9960 can be a frustrating issue that hinders the smooth progress of your sewing projects. Understanding the common causes and implementing effective troubleshooting steps can help address this problem and ensure a more enjoyable sewing experience.

Common Causes of Skipped Stitches:

- Incorrect Needle Size: Using the wrong needle size for the fabric being sewn can lead to skipped stitches. Ensure you choose the appropriate needle size based on the fabric’s weight and type.

- Needle Dullness or Damage: A dull or damaged needle may struggle to pierce through the fabric, resulting in skipped stitches. Regularly replace needles and choose the right type for your sewing task.

- Thread Tension Issues: Incorrect tension on the upper or lower thread can cause stitches to skip. Check and adjust the thread tension according to your machine’s manual.

- Improper Threading: Ensure the machine is threaded correctly, passing through all guides and tension discs. Improper threading can lead to uneven stitching and skipped stitches.

- Bobbin Problems: Issues with the bobbin, such as incorrect insertion or winding, can contribute to skipped stitches. Verify that the bobbin is properly inserted and wound.

- Fabric Type and Condition: Certain fabrics, especially those prone to fraying, can cause skipped stitches. Ensure the fabric is stable and not excessively worn or damaged.

Troubleshooting Steps to Resolve Stitch Skipping Issues:

- Check Needle Size and Condition: Verify that you are using the correct needle size for your fabric. Replace the needle if it is dull or damaged.

- Inspect Thread Tension: Check both upper and lower thread tensions. Make adjustments as needed based on your machine’s manual.

- Ensure Proper Threading: Re-thread the machine, following the threading path outlined in the manual. Pay attention to threading through all guides and tension discs.

- Examine Bobbin and Bobbin Case: Confirm that the bobbin is inserted correctly and wound properly. Inspect the bobbin case for any issues that may be affecting thread tension.

- Evaluate Fabric Stability: Choose stable fabrics to avoid skipping stitches. If working with delicate or fraying fabrics, consider using a stabilizer to enhance stitching.

Tips for Preventing Skipped Stitches in the Future:

- Regular Maintenance: Keep your Singer Quantum Stylist 9960 well-maintained by cleaning lint, oiling moving parts, and replacing needles regularly.

- Use High-Quality Thread: Invest in good-quality thread to minimize thread-related issues that can lead to skipped stitches.

- Test Stitches on Scrap Fabric: Before starting a project, test stitches on a scrap piece of fabric to ensure proper tension and stitching.

- Choose the Right Needle and Thread Combination: Match the needle type and size with the thread and fabric being used to promote smooth stitching.

Here you can find all the parts and accessories for the Singer Quantum Stylist 9960 guaranteed to fit your sewing machine

Singer Quantum Stylist 9960 breaking needles

Why Your Singer Quantum Stylist 9960 Sewing Machine Needle Keeps Breaking? If you find that your Singer Quantum Stylist 9960 Sewing Machine constantly has broken needles, it is important to identify the cause of this occurrence in order to prevent any further damage. There are many different potential issues that can lead to needle breakage and identifying them will save time and effort from having to replace them regularly.

Troubleshooting Singer Quantum Stylist 9960 Needle Problems

The Singer Quantum Stylist 9960 Sewing Machine may suffer from needle breakages as a result of various causes. To address this issue, it is important to check the bobbin case for blockage or misalignment; adjust the tension and pressure of the presser foot; choose the correct size and type of needle; select an appropriate thread weight for your fabric; and maintain balanced thread tensions.

Taking these steps can help reduce broken needles and keep your sewing machine running properly.

Singer Quantum Stylist 9960 upper thread breaking

Upper thread breakage on the Singer Quantum Stylist 9960 sewing machine can be caused by several factors such as incorrect installation, improper tension settings, a damaged or bent needle, incorrect lower thread tension, problems with the bobbin thread winding and/or embroidery data design system settings.

Troubleshooting Singer Quantum Stylist 9960 Upper thread breakage

- To fix these issues, start by rethreading the machine according to the instructions.

- Then check and adjust the upper thread tension, making sure it is not set too tight.

- Also make sure that the needle is correctly inserted with the flat side facing the back and pushed up into the machine as far as possible.

- Next, adjust the lower thread tension so that it rolls out of the bobbin case smoothly.

- Make sure the bobbin is wound so that it is about 80% full and that the thread is evenly wound.

- If using embroidery data, correct any issues with the thread density and overstitching settings in the design system as well as removing any stitches with a pitch of zero or too small of a pitch.

- Make sure to firmly set the fabric in the embroidery frame so that it is taut. Also make sure to use a bobbin designed specifically for this machine and the correct thread and needle.

- Finally, remove any loose thread from the hook area or knots/tangles from the thread as well as replacing any aged, weak thread.

Following these steps should help to solve any upper thread breaking issues on the Singer Quantum Stylist 9960 sewing machine.

Common Singer Quantum Stylist 9960 bobbin thread problems

Singer Quantum Stylist 9960 bobbin thread problems can lead to thread breakage and other machine issues. Here are some common ones and ways to fix them.

Troubleshooting Singer Quantum Stylist 9960 bobbin thread problems

- Wrong Type of Bobbin – If the bobbin being used is not compatible with the Singer Quantum Stylist 9960 sewing machine, it may cause thread breakage. To prevent this, always be sure to use the correct type of bobbin for your machine.

- Bobbin Thread is Low or Out – If the bobbin thread is running low or out, it can cause thread breakage. Make sure that there is an adequate amount of thread on the bobbin before beginning a project.

- Bobbin is Overwound – An overwound bobbin can create too much tension on the thread, resulting in breakages. To prevent this, make sure to wind the bobbin properly and not overfill it.

- Bobbin Case Not Properly Inserted into the Machine – If the bobbin case is not correctly inserted into the machine, it can cause thread breakage. Be sure that the bobbin case is properly inserted before starting a project.

- Bobbin Tail Too Short – If the tail of the bobbin is too short or worn, it can put too much tension on the thread and lead to breaks. To fix this, use a new bobbin with a longer tail.

- Improper Bobbin Tension or Dirty Bobbin Case – If the bobbin tension is incorrect or the bobbin case is dirty, it can cause thread breakage. Adjust the bobbin tension and make sure that the area around the bobbin case is clean before starting a project.

- Damaged Bobbin Case – If the bobbin case is damaged, it can lead to thread breakage. Replace the bobbin case if it is damaged or not functioning properly.

By checking for these common issues and taking steps to fix them, you can help prevent Singer Quantum Stylist 9960 bobbin thread problems and ensure smooth operation of your machine.

Here you can find all the parts and accessories for the Singer Quantum Stylist 9960 guaranteed to fit your sewing machine

Common Singer Quantum Stylist 9960 fabric problem

Why Is My Singer Quantum Stylist 9960 Sewing Machine Not Moving the Fabric? Sewing problems with the Singer Quantum Stylist 9960 can be frustrating and stressful, but understanding their causes and learning how to fix them can help make projects much easier. Issues such as thread tension, incorrect threading, or layers of fabric being sewn together too tightly can all cause your machine to fail to move the fabric properly.

Troubleshooting fabric movement problems on the Singer Quantum Stylist 9960

If you experience any of these problems, the first step is to troubleshoot and find the source of the issue. To do this, check your thread tension by either referring to your machine’s manual or looking for a dial on the side of the machine that controls it. You should also make sure your fabric layers are not too thick or that you have threaded the machine correctly.

In addition, make sure to clean and oil your Singer Quantum Stylist 9960 regularly according to the manufacturer’s instructions. This is important for preventing any mechanical issues from arising in the future. With proper maintenance and regular care, your machine should be able to move fabric properly with no problems!

Common Singer Quantum Stylist 9960 bobbin winding problems. Bobbin winder not spinning

One common problem when using the Singer Quantum Stylist 9960 is that the bobbin winder may not be spinning, even when the machine’s power switch is in the “On” position. This issue can be caused by either an old and worn out bobbin tire or an incorrect adjustment of the winder assembly.

Troubleshooting Bobbin winder problems on the Singer Quantum Stylist 9960

- To address this problem, first remove the top cover and loosen the two screws that hold the winder assembly in place. Gently nudge it closer to the hand wheel side. Be careful not to move it too far, as this may cause the winder to constantly spin.

- Next, inspect the rubber tire of your Singer Quantum Stylist 9960’s bobbin winder to check if it has a flat spot or is worn out. If it is, then you need to replace the tire in order to fix the problem. If not, adjust the position of the bobbin winder until it spins smoothly and properly when powered on.

With these steps you should be able to solve this issue and get your Singer Quantum Stylist 9960 back to its peak performance.

Singer Quantum Stylist 9960 Keep Jamming

Jamming on the Singer Quantum Stylist 9960 sewing machine is a common problem that can occur due to several different causes. Tangled thread, uneven fabric feeding and build ups of lint or dust are all potential culprits. The needle may also hit something inside the machine, so always be aware when using it.

Troubleshooting Jamming Problems on the Singer Quantum Stylist 9960

- To solve this issue, first refer to the troubleshooting steps in the user manual, or follow the instructions in this article. If these methods don’t work, take your machine to a professional repair service.

- To prevent jamming, regularly clean out the lint trap and wipe down the outside of the machine with a soft cloth.

- Additionally, oiling all moving parts as much as necessary can help keep them running smoothly. Refer to the manual for instructions on which parts need to be oiled and how frequently they should be done.

Following these simple steps can help prevent any future jamming issues with your Singer Quantum Stylist 9960 sewing machine.

Singer Quantum Stylist 9960 sewing machine bobbin tension problems

Bobbin tension problems are common in Singer Quantum Stylist 9960 sewing machines and can be caused by a number of factors, including improper thread installation or an improperly adjusted needle plate. Fortunately, there are several easy solutions to fix this issue.

Troubleshooting Singer Quantum Stylist 9960 bobbin tension problems

- The first step is to make sure that the bobbin is properly installed. It should be inserted in the machine with the thread running in a counterclockwise direction. The bobbin case should also be correctly aligned so that the tension spring is facing up, and the black tab should be lined up with the notch in the middle of the case.

- Next, make sure that your needle plate is properly adjusted. This can be done by loosening the screw on the needle plate and gently moving it up or down until it’s even with the feed dog.

- If these steps don’t resolve your bobbin tension issues, you may need to adjust the tension dial on the side of your machine. This can be done by simply turning it clockwise until you find the proper tension.

- Finally, if all else fails, try replacing your bobbin case with a new one. This should resolve any lingering problems that you may have had with the old one.

By following these steps, you should be able to easily solve any bobbin tension problems you may experience while using a Singer Quantum Stylist 9960 sewing machine.

Here you can find all the parts and accessories for the Singer Quantum Stylist 9960 guaranteed to fit your sewing machine

Singer Quantum Stylist 9960 bobbin holder problems

Singer Quantum Stylist 9960 Sewing Machine Bobbin Holder Came Out? The Singer Quantum Stylist 9960 sewing machine may experience problems with its bobbin case. This typically occurs when the bobbin holder is removed and re-inserted, only to find it will not fit back into place. The most likely causes of this problem are dirt, worn-out bobbin cases, or incorrect bob cases for the machine model.

Troubleshooting Singer Quantum Stylist 9960 bobbin holder problems

In order to address this issue, check whether or not the bobbin holder’s finger is properly seated in the small groove located in the needle plate. It may be helpful to slightly adjust its position by gently pressing down on it with a pencil eraser while simultaneously pushing up on the bobbin case latch with a pin.

If this does not work, the bobbin case may need to be cleaned. This can be done by taking a cotton swab and gently wiping around the inside of the bobbin holder’s latch area, as well as the needle plate groove that holds it in place. Additionally, use a compressed air canister or an air compressor to blow out any dust or debris that may have accumulated.

It is also important to ensure the bobbin case being used is compatible with the Singer Quantum Stylist 9960 sewing machine model. If a different type of bobbin case is being utilized, it may not fit properly into place and cause further issues. To avoid this issue, only use bobbins specifically designed for the Singer Quantum Stylist 9960.

Singer Quantum Stylist 9960 Sewing Machine Tension Problems

The Singer Quantum Stylist 9960 sewing machine is a great option for beginners and experienced sewers alike. However, one common issue that may be encountered is tension problems. This can happen when the upper thread is not properly placed in the needle or when the bobbin thread has been wound too tightly. Poorly threaded needles can often cause the upper thread to bunch up and cause tension problems.

Troubleshooting tension problems on the Singer Quantum Stylist 9960

To troubleshoot the Singer Quantum Stylist 9960 sewing machine for tension issues, first check that the needle is properly threaded. Also, make sure that your bobbin thread has not been wound too tightly or unevenly as this can also affect the tension. Next, check that all tension discs are in place and properly adjusted. Finally, make sure you are using the correct needle size for your fabric type as this too can affect the tension.

Singer Quantum Stylist 9960 Sewing Machine Noise Issues

Experiencing unusual noises from your Singer Quantum Stylist 9960 sewing machine can be disconcerting, but understanding the types of sounds, implementing effective troubleshooting steps, and adhering to proper maintenance practices can help address and prevent these noise issues.

Identifying Different Types of Noises Your Machine Might Make:

- Clicking or Ticking Sounds: This could indicate an issue with the needle or its insertion. Check for a bent needle or ensure it is correctly positioned.

- Grinding Noises: Grinding sounds may signal a problem with the machine’s gears or internal components. It’s crucial to address this promptly to prevent further damage.

- Whirring or Whining Sounds: These noises may be related to the motor or belt. Inspect the motor for obstructions or wear, and check the belt for proper tension.

- Clunking or Banging Sounds: These loud noises may suggest a mechanical problem. Investigate for loose parts, screws, or any foreign objects caught in the machine.

- Squeaking or Scratching Sounds: These sounds often point to friction between moving parts. Lubrication or adjustment of components may be necessary.

Troubleshooting Steps for Addressing Unusual Sounds During Operation:

- Inspect the Needle: Ensure the needle is correctly inserted and not bent. Replace the needle if needed, as a damaged needle can create clicking or ticking noises.

- Examine Gears and Internal Components: Carefully inspect the machine’s gears and internal components for any signs of damage or wear. If grinding noises persist, seek professional assistance.

- Check Motor and Belt: Examine the motor for obstructions and signs of wear. Adjust the tension on the belt if necessary, or replace it if it’s worn out.

- Tighten Loose Parts: If clunking or banging sounds are present, check for loose parts or screws. Tighten any components that may have become dislodged.

- Lubricate Moving Parts: Squeaking or scratching sounds may indicate friction. Lubricate moving parts as recommended in the machine’s manual to reduce friction and noise.

- Remove Foreign Objects: Inspect the machine for any foreign objects that may have accidentally entered the working area. Remove these objects carefully.

Maintenance Tips to Keep Your Machine Running Quietly:

- Regular Cleaning: Clean the machine regularly, removing lint, dust, and debris from the bobbin area, feed dogs, and other critical parts.

- Proper Lubrication: Follow the manufacturer’s instructions for lubricating moving parts. Proper lubrication reduces friction and minimizes noise.

- Replace Worn Components: Regularly inspect belts, gears, and other components for signs of wear. Replace any worn-out parts promptly to prevent noise issues.

- Professional Servicing: Schedule periodic professional servicing to ensure that internal components are in good condition and functioning correctly.

- Storage and Covering: Store the sewing machine in a clean, dry area and use a cover to protect it from dust when not in use.

Singer Quantum Stylist 9960 Sewing Machine Parts

The Singer Quantum Stylist 9960 sewing machine may experience problems with parts and components due to normal wear and tear, improper use, or age. If any of these problems arise, it is important to identify the cause of the issue quickly, in order to prevent further damage to your machine.

Here you can find all the parts and accessories for the Singer Quantum Stylist 9960 guaranteed to fit your sewing machine

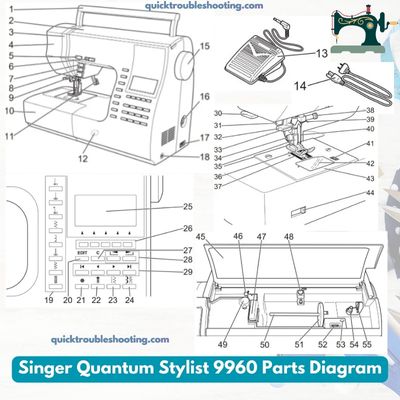

Singer Quantum Stylist 9960 Parts Diagram

Singer Quantum Stylist 9960 MAIN PARTS

- Handle

- Top Cover

- Thread Take-Up Lever (Inside)

- Face Plate

- Thread Cutter Button

- Speed Control Button

- Needle Up-Down / Slow Button

- Reverse Stitch Button

- Start/Stop Button

- Extension Table (Accessories)

- Presser Foot Lifter

- Forward / Reverse Adjusting Screw (underneath machine)

- Foot Controller

- Power Line Cord

- Hand Wheel

- Power Switch

- Terminal Box

- Controller Jack

- Direct Stitch Selection Buttons

- EDIT Button

- Tack Button

- Twin Needle Button

- Utility Stitch Button

- Decorative Stitch & Letter Button

- Liquid Crystal Display (L.C.D.)

- Function Buttons (F1 – F5)

- Clear Button

- Scroll Buttons

- Cursor Buttons

- Thread Cutter

- Buttonhole Lever

- Needle Threader Lever

- Needle Threader

- Presser Foot Thumb Screw

- Presser Foot Holder

- Presser Foot

- Fabric Feed Dogs

- Needle Clamp Screw

- Needle Thread Guide

- Needle

- Bobbin Cover Latch

- Bobbin Cover

- Needle Plate

- Drop Feed Lever

- Pattern Chart

- Thread Guide

- Thread Guide

- Bobbin Winder Thread Guide

- Thread Tension Regulator

- Spool Stand

- Felt Washer

- L.C.D. Contrast Control

- Auxiliary Spool Holder

- Bobbin Winder Shaft

- Bobbin Winder Stop

It is worth noting that the most common problems with Singer Quantum Stylist 9960 parts include the following problems:

Singer Quantum Stylist 9960 Sewing Machine Presser Foot Problems

The presser foot is a crucial component of the Singer Quantum Stylist 9960 sewing machine, playing a key role in guiding the fabric during stitching. If you encounter issues with the presser foot, it can affect the overall performance of your machine.

Here, we discuss some common problems associated with presser feet, their possible causes, and effective solutions to address them.

| Presser Foot Problem | Causes | Solution |

|---|---|---|

| Presser Foot Won’t Lower | Misalignment in the presser foot mechanism or a malfunction in the presser foot lifter. | Ensure correct alignment, check for obstacles, and consult the machine’s manual for adjusting the presser foot lifter if needed. |

| Presser Foot Won’t Stay Up | Loose presser foot lifter or a faulty spring mechanism. | Tighten loose components related to the presser foot lifter. Seek professional assistance for repair or replacement if the spring is faulty. |

| Uneven Pressure on Fabric | Imbalanced presser foot due to misalignment or damage. | Inspect the presser foot for visible damage. Replace if necessary and adjust the alignment following the machine’s manual. |

| Presser Foot Tension Issues | Inconsistent tension due to a damaged tension spring or debris. | Clean the presser foot tension area from lint or debris. For a damaged spring, seek professional repair or replacement. |

| Difficulty in Changing Presser Feet | Tight or misaligned presser foot holder. | Loosen the presser foot holder screw slightly for easier changes. Ensure proper alignment when attaching a new presser foot. |

| Presser Foot Drags on Fabric | Low presser foot lifter, incorrect pressure, or a damaged foot. | Adjust the presser foot lifter to the appropriate height. Check and adjust the presser foot pressure for the fabric. Replace the foot if damaged. |

Preventive Measures:

- Regular Cleaning: Clean the presser foot area regularly, removing any lint, dust, or debris that may affect its performance.

- Proper Storage: Store your sewing machine with the presser foot in the raised position to prevent unnecessary pressure on the foot.

- Gentle Handling: Handle the presser foot and its components gently to avoid damage.

- Use the Right Presser Foot: Ensure you are using the correct presser foot for the type of stitching or fabric you are working with.

Here you can find all the parts and accessories for the Singer Quantum Stylist 9960 guaranteed to fit your sewing machine

Singer Quantum Stylist 9960 Sewing Machine Motor Problems

The motor is a vital component of the Singer Quantum Stylist 9960 sewing machine, powering its operation. If you encounter issues with the motor, it can significantly impact the machine’s performance.

Here, we provide information about the most common problems associated with the sewing machine motor, their potential causes, and effective solutions for troubleshooting.

| Sewing Machine Motor Problem | Causes | Solution |

|---|---|---|

| Motor Not Running | Issues with power supply, faulty foot pedal, or motor damage. | Ensure proper machine plug-in, check foot pedal connection, inspect the motor for visible damage. Seek professional repair if the motor remains non-functional. |

| Motor Running Slowly | Loose or damaged drive belt, lack of lubrication, or internal motor issues. | Tighten or replace the drive belt, lubricate moving parts as per the manual, inspect the motor for internal problems. Seek professional assistance if the issue persists. |

| Motor Overheating | Prolonged use, inadequate ventilation, or an overloaded machine. | Allow the motor to cool down after extended use, ensure proper ventilation, avoid overloading with heavy fabrics. Consult a professional if overheating persists. |

| Unusual Motor Sounds | Grinding, buzzing, or squeaking indicating internal motor issues or loose components. | Inspect the motor for loose parts, debris, or visible damage. Lubricate moving parts if needed. Seek professional diagnosis and repair if unusual sounds persist. |

| Motor Vibrations | Excessive vibrations from an imbalanced motor, loose screws, or worn-out motor bearings. | Check for loose screws, tighten them, inspect motor bearings for wear, and replace if necessary. Seek professional assistance if vibrations continue. |

Preventive Measures:

- Regular Cleaning: Keep the motor and surrounding areas clean from dust and debris to prevent overheating and maintain optimal performance.

- Proper Lubrication: Follow the manufacturer’s guidelines for lubricating the motor and moving parts to reduce friction and minimize wear.

- Avoid Overloading: Avoid overloading the machine with heavy fabrics or sewing tasks beyond its recommended capacity to prevent strain on the motor.

- Monitor Usage Time: Take breaks during extended sewing sessions to prevent the motor from overheating. Allow the machine to cool down as needed.

- Professional Servicing: Schedule periodic professional servicing to ensure the motor’s internal components are in good condition and functioning correctly.

Singer Quantum Stylist 9960 Sewing Machine Belt Problems

The belt in a sewing machine is a crucial component that facilitates the transfer of power from the motor to the moving parts, allowing for smooth and efficient operation. If you encounter issues with the belt in your Singer Quantum Stylist 9960 sewing machine, addressing them promptly is essential.

Here, we provide information about the most common belt problems, their potential causes, and effective solutions for troubleshooting.

| Sewing Machine Belt Problem | Causes | Solution |

|---|---|---|

| Belt Slipping | Loose or worn-out belt, inadequate tension, or improper alignment. | Tighten or replace the belt. Adjust tension according to the machine’s manual. Ensure proper alignment for smooth operation. |

| Belt Breakage | Excessive wear, overuse, or tension issues. | Replace the belt with a new one. Ensure it is the correct size and type. Avoid overloading the machine and follow maintenance practices. |

| Belt Misalignment | Improper installation, wear, or tension discrepancies. | Reinstall the belt following the machine’s manual. Check for wear and adjust tension for proper alignment. |

| Excessive Belt Noise | Loose or misaligned belt, debris, or insufficient lubrication. | Tighten the belt, clean debris, and lubricate moving parts as per the manual. If noise persists, inspect the belt for wear or damage. |

| Belt Tension Issues | Damaged tension spring or misadjustment. | Inspect the tension spring for damage and replace if necessary. Adjust the tension according to the machine’s guidelines. |

Preventive Measures:

- Regular Inspection: Regularly inspect the belt for signs of wear, damage, or misalignment. Replace it at the first indication of issues.

- Proper Tension Adjustment: Follow the machine’s manual for proper tension adjustment to prevent slipping or excessive tension on the belt.

- Avoid Overloading: Avoid overloading the machine with heavy fabrics or tasks beyond its recommended capacity to prevent strain on the belt.

- Correct Installation: Ensure the belt is correctly installed according to the machine’s manual to prevent misalignment and subsequent issues.

- Lubrication: Follow the manufacturer’s guidelines for lubricating the belt and moving parts to reduce friction and minimize wear.

Singer Quantum Stylist 9960 Sewing Machine Thread Cutter Problems

The thread cutter is a handy feature in the Singer Quantum Stylist 9960 sewing machine that facilitates efficient and precise cutting of threads. If you encounter issues with the thread cutter, addressing them promptly ensures uninterrupted sewing.

Here, we provide information about the most common thread cutter problems, their potential causes, and effective solutions for troubleshooting.

| Sewing Machine Thread Cutter Problem | Causes | Solution |

|---|---|---|

| Thread Cutter Not Cutting | Dull or damaged cutting blades, thread caught in the cutter, or misalignment. | Inspect and replace dull or damaged blades. Remove any trapped thread. Ensure proper alignment of the cutter mechanism. |

| Uneven Cutting | Blade misalignment or an accumulation of debris. | Clean the cutter area to remove any debris. Adjust the blade alignment according to the machine’s manual for uniform cutting. |

| Thread Cutter Jamming | Thread tangles, debris, or a malfunction in the cutter mechanism. | Clear any thread tangles or debris from the cutter area. If the problem persists, consult the machine’s manual for guidance. |

| Blade Dullness | Overuse or cutting through thick materials. | Regularly replace dull blades to ensure efficient cutting. Avoid excessive force when cutting through heavy fabrics. |

| Thread Cutter Not Retracting | Issues with the retraction mechanism, debris, or misalignment. | Clean the cutter area, ensuring there is no debris affecting the retraction. Adjust the mechanism for proper retraction. |

Preventive Measures:

- Regular Maintenance: Perform regular maintenance, including cleaning the thread cutter area and replacing blades as needed.

- Avoiding Excessive Force: Avoid applying excessive force when cutting through thick fabrics to prevent blade damage.

- Proper Thread Placement: Ensure threads are positioned correctly before using the thread cutter to prevent tangles and jams.

- Following Machine Guidelines: Adhere to the machine’s manual for proper usage and maintenance of the thread cutter.

- Blade Replacement Schedule: Establish a schedule for regular blade replacement to maintain optimal cutting performance.

Hand wheel problems on Singer Quantum Stylist 9960 sewing machine

The hand wheel is a crucial component of the Singer Quantum Stylist 9960 sewing machine, allowing manual control over needle movement. If you encounter issues with the hand wheel, addressing them promptly ensures smooth operation.

Here, we provide information about the most common hand wheel problems, their potential causes, and effective solutions for troubleshooting.

Common Sewing Machine Hand Wheel Problems:

| Hand Wheel Problem | Causes | Solution |

|---|---|---|

| Hand Wheel Difficult to Turn | Accumulation of debris, lack of lubrication, or internal mechanism issues | – Clean the hand wheel area, removing any debris. |

| – Apply lubrication following the machine’s manual. | ||

| – If problems persist, seek professional inspection for internal issues. | ||

| Hand Wheel Stuck or Jammed | Thread tangles, fabric jams, or internal obstructions | – Check for thread or fabric jams and clear them. |

| – Inspect the bobbin area for any tangled thread. | ||

| – If the hand wheel remains stuck, consult the machine’s manual or seek professional assistance. | ||

| Hand Wheel Not Engaging Needle | Disengaged clutch, broken drive belt, or internal issues | – Ensure the clutch is engaged by loosening the hand wheel center knob. |

| – Check the drive belt for breakage and replace if necessary. | ||

| – If problems persist, consult the machine’s manual or seek professional assistance. | ||

| Uneven or Rough Hand Wheel Rotation | Lack of lubrication, worn-out bearings, or internal wear | – Apply lubrication to the hand wheel mechanism. |

| – Inspect bearings for wear and replace if needed. | ||

| – If uneven rotation persists, seek professional inspection for internal wear. | ||

| Hand Wheel Spins Freely without Needle Movement | Disengaged clutch or broken internal connection | – Ensure the clutch is engaged by tightening the hand wheel center knob. |

| – If the issue persists, inspect the internal connections or seek professional assistance for repair. |

Preventive Measures:

- Regular Lubrication: Apply lubrication to the hand wheel mechanism as per the machine’s manual.

- Thread and Fabric Inspection: Regularly check for thread tangles or fabric jams that may affect the hand wheel.

- Proper Clutch Engagement: Ensure the clutch is engaged when sewing and disengaged for bobbin winding.

- Timely Maintenance: Schedule periodic maintenance to address any wear or internal issues.

Here you can find all the parts and accessories for the Singer Quantum Stylist 9960 guaranteed to fit your sewing machine

Troubleshooting Guide for Singer Quantum Stylist 9960 Sewing Machine Issues: Table

| Category | Common Issues | Troubleshooting Tips |

|---|---|---|

| Stitch Problems | – Zigzag feature not working – Stitching too tight/loose – Skipped stitches – Difficulty changing stitch length settings | – Adjust upper and lower thread settings – Use the right needle size for fabric – Clean lint build-up – Regular maintenance |

| Breaking Needles | – Frequent needle breakage | – Check bobbin case for blockage or misalignment – Adjust presser foot tension and pressure – Choose correct needle size – Select appropriate thread weight – Maintain balanced thread tensions |

| Upper Thread Breaking | – Upper thread breakage | – Rethread machine – Adjust upper thread tension – Ensure correct needle insertion – Adjust lower thread tension – Properly wind bobbin – Address embroidery data issues – Set fabric taut in embroidery frame – Use suitable bobbin, thread, and needle – Remove loose thread or knots |

| Bobbin Thread Problems | – Thread breakage due to bobbin issues | – Use correct bobbin type – Ensure sufficient bobbin thread – Avoid overwinding – Properly insert bobbin case – Use a new bobbin with a longer tail – Check bobbin tension and cleanliness – Replace damaged bobbin case |

| Fabric Problem | – Sewing machine not moving fabric | – Check thread tension – Ensure correct threading – Avoid sewing thick fabric layers – Regularly clean and oil machine |

| Bobbin Winding Problems | – Bobbin winder not spinning | – Adjust winder assembly position – Inspect and replace worn-out bobbin tire |

| Jamming Issues | – Machine jamming | – Follow user manual troubleshooting – Clean lint trap regularly – Oil moving parts as instructed |

| Bobbin Tension Problems | – Bobbin tension issues | – Properly install bobbin – Adjust needle plate – Adjust tension dial – Replace bobbin case if needed |

| Bobbin Holder Problems | – Bobbin holder not fitting back into place | – Check bobbin holder’s finger seating – Clean bobbin case – Ensure compatibility with machine model |

| Tension Problems | – Upper thread bunching up due to tension issues | – Check needle threading – Avoid overwound bobbin – Ensure proper tension disc adjustment – Use correct needle size |

| Machine Parts Issues | – General problems with machine parts | – Identify and fix parts and components issues – Specific troubleshooting for presser foot, motor, belt, thread cutter, and hand wheel issues |

Singer Quantum Stylist 9960 Manual

The instruction manual for the Singer 9960 Quantum Stylist sewing machine can be found here.

FAQ

Why is my sewing machine not threading my bobbin?

Your sewing machine may not be threading the bobbin correctly due to an incorrectly positioned thread guide or a misaligned spool pin. Check that your thread guide is aligned with the groove on the bobbin case, and make sure your spool pin is in correct position.

Why is my bobbin thread looping underneath?

Bobbin thread looping underneath can be caused by incorrect tension, a dull needle, or the thread not being wound correctly on the bobbin. Check that you are using the correct size and type of needle, adjust the bobbin case tension if necessary, and make sure your bobbin is properly wound.

What causes thread to bunch up underneath when sewing?

Thread bunching underneath when sewing can be caused by incorrect tension or a dull needle. Check that your thread tension is set correctly and use the correct size and type of needle for your project.

How do I get my sewing machine to pick up the bobbin thread?

To get your sewing machine to pick up the bobbin thread, ensure that the presser foot is in its raised position, raise the bobbin thread by turning the hand wheel towards you, and place your fabric under the presser foot. Lower the presser foot and begin sewing.

Conclusion: Singer Quantum Stylist 9960 Common Problems and Troubleshooting

The Singer Quantum Stylist 9960 sewing machine is a reliable and easy-to-use piece of equipment. However, like all other machines, it can suffer from common problems due to normal wear. We have listed the most common problems with this sewing machine as well as briefly stating how to fix them.

For further information about each problem and its solution, please read our other articles. With the knowledge provided in this article and the rest of our content, you can keep your Singer Quantum Stylist 9960 sewing machine running optimally for years to come.

I have had my Quantum 9960 for 5 years and have had several problems with it. At first, I thought it was my not understanding fully the operation instructions. So, I took it to a Singer dealer and paid for a class to help me understand my new machine. It helped a little but other issue started to show up. I got totally discouraged and stopped sewing for a quite a while. Just recently I have tried to concur this machine again. But I am finding even more issues with it. I am so upset with it and ready to get rid of it. I have read your trouble shooting pages but nothing I do works. I am so upset with this machine.

My 9960 isn’t sewing. The needle will not change position. I can hand turn it but when I push the start button it doesn’t move. Help

I cant get. The reverse button to work. I need to be able to reverse for mending

My new Quantum 9960 sews beautiful. It is so slow. Was using Start/Stop button and tried to follow directions to make it sew faster. It did not go much faster. I then plugged in foot pedal. Even with the foot pedal it did not go much faster. Is it suppose to be this slow?