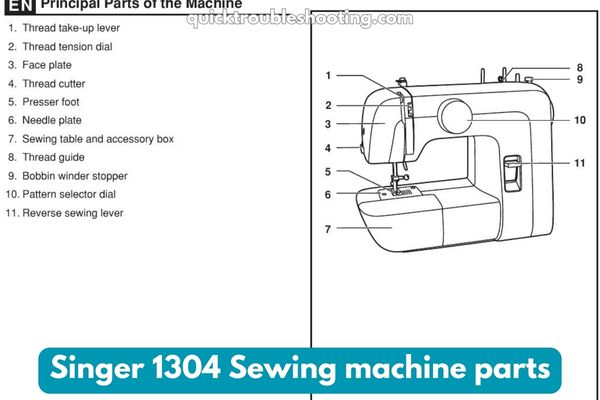

Troubleshooting Singer 1304 Sewing machine parts

The Singer 1304 Start is a lightweight, easy-to use sewing machine that is perfect for all kinds of sewing projects. It features 6 built-in stitches, automatic tensioning and preset stitch length width. Despite its ease of use, the Singer 1304 can still experience some common problems with its parts.

This mini guide will explore some of the common problems related to the Singer 1304, and provide quick fixes for them. With this guide, you’ll be able to quickly and easily troubleshoot your machine so that you can get back to enjoying your sewing projects!

Singer 1304 Sewing machine parts problems and solution

The Singer 1304 sewing machine is a complex device with many components that must be working properly for it to operate. When an issue arises, identifying the root cause of the problem is essential in order to fix it. Common issues include motors that won’t run, motors running but the hand wheel not turning, motors running but the needle not moving, and fabric that won’t feed.

Solutions to these issues can be found by first understanding the components involved and then troubleshooting the problem accordingly. With an understanding of all the parts and their respective functions, it is possible to resolve any problems encountered with this sewing machine.

Singer 1304 sewing machine motor problems

1. When the motor of the sewing machine does not run, the cause could be that the cord is not plugged in or that the power stitch is off. Additionally, the knee or foot accelerator may be jammed or improperly attached to the power source.

2. If the motor runs but the hand wheel does not turn, it is likely that there is thread or lint caught or tangled in the bobbin case area.

3. If the motor, hand wheel and needle move but fabric does not feed, the presser foot may be up, the stitch length regulator may not be set correctly, or the feed dog could be in the lowered position.

4. If the motor, hand wheel, needle and fabric move but no stitch is formed, the cause may be that the needle was disengaged for bobbin winding and not tightened back to sewing position, the thread may have come out of the needle, or that the bobbin and/or case wasn’t inserted correctly.

Singer 1304 sewing machine belt problems

If the needle does not move, it is possible that the motor belt is slipping because it is loose or worn. Additionally, there may need to be more pressure if the fabric is heavy. Additionally, the needle may need to be tightened into its clamp or inserted correctly. Lastly, the timing of the machine might be off.

Singer 1304 sewing machine presser foot problems

The Singer 1304 sewing machine may have problems with the presser foot if it is not adjusted correctly. If the pressure exerted by the presser foot onto the fabric is too low, then it can cause issues such as a lack of feeding or puckering of the material. Additionally, incorrect attachment of the presser foot may lead to improper stitches or general fabric issues. To avoid this, it is important to ensure that the presser foot is set at the right pressure and securely attached.

How To Fix Presser Foot On Singer

If your machine is having issues stitching or the fabric isn’t being held steady, it could be due to the presser foot’s height being set incorrectly. To fix this, you need to loosen the clamp screw and adjust the foot accordingly (usually 5/16 inch for most fabrics).

Firstly, take off the faceplate and presser foot pressure knob from the Singer sewing machine. See if the presser bar can be lubricated from the manual, then lift the needle and foot such that it’s above the foot and feed dogs are down. Check if the foot is lying flat on the throat plate before altering its height by loosening the clamp screw. Be sure to secure it after the adjustment and return the pressure knob and faceplate.

Singer 1304 sewing machine thread cutter problems

The automatic thread cutter can get clogged with lint easily, and cleaning it out may be difficult. Turn off the sewing machine and disassemble its parts, cleaning each one individually. Once everything is reassembled, the thread cutter should operate without any issues. Cleaning the machine properly will ensure that your projects can be finished without any hindrances.

Hand wheel problems on Singer 1304 sewing machine

The handwheel on a Singer 1304 sewing machine can become difficult to turn for various reasons, ranging from incorrect threading to a build-up of lint and dust. Additionally, the belt may be broken or there may not be enough oil in the machine. Therefore, it is important to check all these potential causes before attempting any fixes. Additionally, preventive measures such as regularly cleaning the machine and oiling the gears can help avoid future malfunctions.

How To Fix Sewing Machine Handwheel

Fixing a sewing machine handwheel can be tricky, but there are several methods to try. Adjusting the inner knob on older machines and rethreading the unit can help loosen it up. If this doesn’t work, cleaning out any lint from the bobbin case may do the trick. Taking these steps should make it easier to turn the handwheel again.

How Should You Turn A Sewing Machine Handwheel?

Always turn the handwheel of a sewing machine in an anti-clockwise direction to avoid damage to the motor and costly repairs. Turning it clockwise should only be done if there is a thread jam that needs unravelling. This isn’t usually explained in manuals, so it’s important to remember.

Other Sewing Machine Parts Problems

- If the machine runs sluggishly, it may be because the bobbin winder is still engaged, the knee or foot control is improperly positioned, or the machine may need oiling and/or cleaning.

- If the machine runs noisily, it is probably due to a lack oiling and/or cleaning, the needle being bent and hitting against the foot or throat plate, bobbin and/or case not being tight enough, or the bobbin nearly out of thread.

- If the machine will not stitch in reverse, this could be because it is an older model and does not have this capability, or the stitch control may be set for “stretch stitch” or “buttonhole”.

Singer 1304 Sewing Machine Troubleshooting Guide

Here is a table summarizing the Singer 1304 sewing machine parts problems and their solutions:

| Problem | Possible Causes | Solutions |

|---|---|---|

| Motor Not Running | 1. Cord not plugged in. 2. Power switch off. 3. Jammed or improperly attached knee/foot accelerator. | Check cord connection, turn on power switch, ensure proper attachment of accelerator. |

| Hand Wheel Not Turning (Motor Running) | Thread or lint caught/tangled in bobbin case area. | Clear thread/lint from the bobbin case area. |

| Fabric Not Feeding | Presser foot up, incorrect stitch length regulator setting, feed dog in lowered position. | Lower presser foot, adjust stitch length regulator, ensure feed dog is in the correct position. |

| No Stitch Formed | Needle disengaged for bobbin winding, thread out of the needle, incorrect bobbin insertion. | Re-engage needle, thread needle, ensure correct bobbin insertion. |

| Motor Belt Slipping | Loose or worn motor belt, insufficient pressure for heavy fabric, needle not tightened or inserted correctly, timing issues. | Tighten or replace motor belt, increase pressure for heavy fabric, ensure correct needle insertion, check and adjust machine timing. |

| Presser Foot Issues | Incorrectly adjusted presser foot pressure, improper attachment causing stitching/fabric issues. | Adjust presser foot pressure, ensure correct attachment of the presser foot. |

| Needle Not Moving (Belt Related) | Loose or worn motor belt, insufficient pressure for heavy fabric, needle not tightened or inserted correctly, timing issues. | Tighten or replace motor belt, increase pressure for heavy fabric, ensure correct needle insertion, check and adjust machine timing. |

| Thread Cutter Clogged | Accumulated lint in the automatic thread cutter. | Turn off machine, disassemble and clean thread cutter components, reassemble. |

| Hand Wheel Difficult to Turn | Incorrect threading, lint/dust buildup, broken belt, insufficient oil. | Check threading, clean lint/dust, replace broken belt, lubricate gears, ensure sufficient oil. |

| Machine Runs Sluggishly | Bobbin winder engaged, improper knee/foot control positioning, machine needs oiling/cleaning. | Disengage bobbin winder, reposition knee/foot control, oil and clean machine. |

| Machine Runs Noisily | Lack of oiling/cleaning, bent needle hitting foot/throat plate, loose bobbin and/or case, nearly empty bobbin. | Oil and clean machine, replace bent needle, tighten bobbin and/or case, refill bobbin. |

| Machine Won’t Stitch in Reverse | Older model without reverse stitching capability, stitch control set for “stretch stitch” or “buttonhole”. | Check machine model capabilities, adjust stitch control settings. |

Note: Always refer to the Singer 1304 sewing machine manual for specific instructions and guidelines related to troubleshooting and maintenance.

Conclusion: Troubleshooting Singer 1304 Sewing machine parts

In conclusion, Singer 1304 sewing machines have some common issues that can be easily fixed with a few simple maintenance steps. It is important to check for thread jams and other fabric issues, as well as ensuring the presser foot is set at the right pressure and securely attached.

Additionally, making sure to clean the machine’s parts regularly and oil the gears will help ensure it is running smoothly and efficiently. With these tips, you should be able to easily keep your Singer 1304 sewing machine running well.