Solving Tension Problems with a Pfaff Sewing Machine

Having trouble with your PFAFF sewing machine tension? You’re not alone. Many sewers have experienced tension issues with their PFAFF machines, and it can be a frustrating problem to solve. Fortunately, there are a few steps you can take to troubleshoot and fix the tension on your PFAFF sewing machine.

Common Causes of Pfaff Sewing Machine Tension Problems

- Incorrect thread tension

- Needle size not suitable for the thread

- Thread not properly inserted into the needle

- Bobbin tension not adjusted correctly

- Thread not properly wound on the bobbin

- Needle not inserted correctly

- Needle not suitable for the fabric

- Incorrect stitch length

- Incorrect stitch width

- Machine not properly threaded (PFAFF)

Troubleshooting PFAFF Sewing Machine Tension Problems

This section will detail the common causes of tension problems with PFAFF sewing machines and provide instructions on how to troubleshoot them.

Here you can find all the parts and accessories for the PFAFF Sewing Machine guaranteed to fit your sewing machine

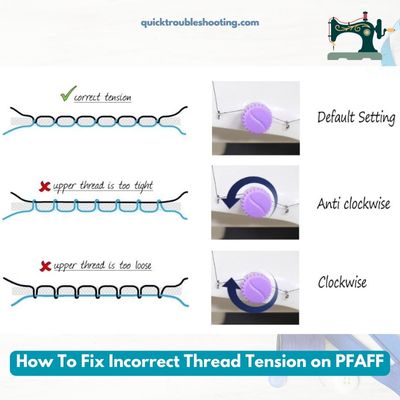

Incorrect Thread Tension on PFAFF Sewing Machines

Incorrect thread tension is one of the most common problems encountered when using a PFAFF sewing machine. If the tension is too tight, the thread will be pulled too tightly through the fabric, resulting in puckering and uneven stitches. If the tension is too loose, the thread will not be pulled through the fabric properly, resulting in skipped stitches and loose loops.

Examples of Incorrect Thread Tension

- Thread is pulled too tightly through the fabric, resulting in puckering and uneven stitches.

- Thread is pulled too loosely through the fabric, resulting in skipped stitches and loose loops.

- Thread is pulled unevenly through the fabric, resulting in uneven stitches.

Step-by-Step Instructions for Fixing Incorrect Thread Tension on PFAFF Sewing Machines

- Turn the hand wheel to raise the needle to its highest position.

- Locate the tension control knob on the front of the machine.

- Turn the tension control knob to the left to loosen the tension, or to the right to tighten the tension.

- Thread the machine with the new tension setting.

- Test the tension by sewing a few stitches on a scrap of fabric.

- If the tension is still incorrect, repeat steps 3-5 until the desired tension is achieved.

Once the correct tension is achieved, the stitches should be even and the thread should be pulled through the fabric smoothly. If the tension is still incorrect after several attempts, it may be necessary to consult a professional for further assistance.

Needle Size Not Suitable for the Thread

Using the wrong needle size for the thread can cause a variety of problems, from skipped stitches to broken needles. It is important to select the correct needle size for the thread you are using to ensure a successful sewing project.

What is the Right Needle Size?

The right needle size for the thread depends on the type of thread and the fabric you are using. Generally, the heavier the thread, the larger the needle size should be. For example, if you are using a heavy-weight thread, such as a topstitching thread, you should use a larger needle size than if you were using a lightweight thread, such as a quilting thread.

The fabric type also affects the needle size. For example, if you are sewing on a thick fabric, such as denim, you should use a larger needle size than if you were sewing on a lightweight fabric, such as chiffon.

Pfaff Needle Size Chart

Pfaff offers a needle size chart to help you select the right needle size for your project. The chart is divided into two sections: one for general sewing and one for embroidery. The general sewing section includes needle sizes from 60/8 to 110/18, while the embroidery section includes needle sizes from 75/11 to 110/18. The chart also includes a description of the type of thread and fabric that each needle size is suitable for.

How to Fix Needle Size Not Suitable for the Thread

If you have selected the wrong needle size for the thread, there are a few steps you can take to fix the problem:

- Check the needle size chart to make sure you have selected the correct needle size for the thread.

Thread Not Properly Inserted into the Needle: PFAFF

When threading a PFAFF sewing machine, it is important to ensure that the thread is properly inserted into the needle. If the thread is not properly inserted, it can cause the machine to malfunction, resulting in skipped stitches, uneven tension, and other problems. Fortunately, it is relatively easy to fix this issue.

Step-by-Step Instructions

- Turn off the machine and unplug it from the power source.

- Raise the presser foot and remove the needle.

- Check the needle for any damage or burrs. If the needle is damaged, replace it with a new one.

- Thread the needle from the front to the back, making sure that the thread is inserted all the way through the eye of the needle.

- Pull the thread through the eye of the needle until there is a loop of thread on the back side of the needle.

- Insert the needle into the machine, making sure that the flat side of the needle is facing the back of the machine.

- Lower the presser foot and turn on the machine.

- Test the machine by sewing a few stitches.

Examples

If the thread is not properly inserted into the needle, it can cause the machine to malfunction. For example, the machine may skip stitches, the tension may be uneven, or the thread may break. In some cases, the machine may even stop working altogether.

In order to prevent these issues, it is important to make sure that the thread is properly inserted into the needle. If the thread is not properly inserted, the

Here you can find all the parts and accessories for the PFAFF Sewing Machine guaranteed to fit your sewing machine

Bobbin Tension Not Adjusted Correctly

Bobbin tension is an important part of sewing with a PFAFF sewing machine. If the bobbin tension is not adjusted correctly, it can cause problems with the stitches, such as skipped stitches, uneven stitches, and thread bunching. Fortunately, it is easy to adjust the bobbin tension on a PFAFF sewing machine.

Examples of Bobbin Tension Not Adjusted Correctly

- Skipped stitches

- Uneven stitches

- Thread bunching

- Loose stitches

- Thread breakage

Step-by-Step Instructions for Adjusting Bobbin Tension on a PFAFF Sewing Machine

- Remove the bobbin case from the machine.

- Locate the tension screw on the bobbin case.

- Turn the tension screw clockwise to increase the tension, or counterclockwise to decrease the tension.

- Test the tension by winding a few inches of thread onto the bobbin.

- Hold the bobbin in one hand and the thread in the other. Gently pull the thread away from the bobbin. The thread should unwind from the bobbin with a slight resistance.

- If the tension is too loose, turn the tension screw clockwise a quarter turn and repeat the test.

- If the tension is too tight, turn the tension screw counterclockwise a quarter turn and repeat the test.

- Continue adjusting the tension until the thread unwinds from the bobbin with a slight resistance.

Thread Not Properly Wound on the Bobbin: PFAFF

Thread not properly wound on the bobbin is a common issue for PFAFF sewing machines. This issue can cause skipped stitches, thread breakage, and tension problems. Fortunately, it is relatively easy to fix. Below are step-by-step instructions on how to properly wind the bobbin on a PFAFF sewing machine.

Examples of Thread Not Properly Wound on the Bobbin

- Thread is wound too loosely on the bobbin.

- Thread is wound unevenly on the bobbin.

- Thread is wound too tightly on the bobbin.

- Thread is wound in the wrong direction on the bobbin.

Step-by-Step Instructions

- Remove the bobbin from the machine.

- Cut a length of thread that is approximately twice the circumference of the bobbin.

- Tie the thread to the bobbin.

- Place the bobbin onto the bobbin winder.

- Press the bobbin winder button to start winding the thread onto the bobbin.

- Wind the thread onto the bobbin in a clockwise direction.

- Stop winding when the bobbin is full.

- Cut the thread and remove the bobbin from the bobbin winder.

- Replace the bobbin into the machine.

By following these steps, you should be able to properly wind the bobbin on a PFAFF sewing machine. If you are

Needle Not Inserted Correctly

When using a Pfaff sewing machine, it is important to ensure that the needle is inserted correctly. If the needle is not inserted correctly, it can cause a variety of problems, such as skipped stitches, uneven stitches, and even broken needles. Fortunately, it is easy to fix this issue.

Examples of Needle Not Inserted Correctly

- Needle is inserted at an angle

- Needle is not inserted all the way

- Needle is inserted backwards

Step-by-Step Instructions for Fixing a Pfaff Sewing Machine Needle Not Inserted Correctly

- Turn off the machine and unplug it.

- Remove the needle plate by loosening the screw on the side of the machine.

- Remove the needle by loosening the needle clamp screw.

- Check the needle to make sure it is the correct size and type for your machine.

- Insert the needle into the needle clamp with the flat side of the needle facing the back of the machine.

- Tighten the needle clamp screw.

- Replace the needle plate and tighten the screw.

- Plug in the machine and turn it on.

By following these steps, you should be able to fix the issue of a Pfaff sewing machine needle not inserted correctly. If the issue persists, it may be necessary to take the machine to a professional for further inspection.

Needle Not Suitable for the Fabric

Using the wrong needle for the fabric can cause a variety of problems, from skipped stitches to broken needles. It is important to select the correct needle for the fabric you are working with in order to ensure a successful project.

Examples of Needle Not Suitable for the Fabric

- Using a universal needle on a delicate fabric such as silk or chiffon.

- Using a ballpoint needle on a knit fabric.

- Using a sharp needle on a heavy fabric such as denim.

How to Fix It Using PFAFF

If you are using a PFAFF sewing machine, you can easily fix the problem of a needle not suitable for the fabric by following these steps:

- Turn off the machine and unplug it from the power source.

- Remove the needle from the machine.

- Check the needle size and type to make sure it is suitable for the fabric you are working with.

- If the needle is not suitable, replace it with the correct needle for the fabric.

- Re-insert the needle into the machine and tighten the screw.

- Plug the machine back into the power source and turn it on.

By following these steps, you can easily fix the problem of a needle not suitable for the fabric when using a PFAFF sewing machine.

Incorrect Stitch Length with PFAFF

Incorrect stitch length is a common issue when using a PFAFF sewing machine. It can be caused by a variety of factors, including incorrect thread tension, incorrect needle size, or incorrect stitch settings. If the stitch length is incorrect, it can cause the fabric to pucker or the stitches to be too loose or too tight. Fortunately, it is relatively easy to fix this issue.

Examples of Incorrect Stitch Length

- Stitches that are too long or too short

- Fabric puckering

- Stitches that are too loose or too tight

Step-by-Step Instructions for Fixing Incorrect Stitch Length with PFAFF

- Check the thread tension. If the tension is too tight, the stitches will be too short. If the tension is too loose, the stitches will be too long. Adjust the tension as needed.

- Check the needle size. If the needle is too small, the stitches will be too short. If the needle is too large, the stitches will be too long. Replace the needle with the correct size.

- Check the stitch settings. If the stitch length is set too short, the stitches will be too short. If the stitch length is set too long, the stitches will be too long. Adjust the stitch length as needed.

- Test the stitch length on a scrap of fabric. If the stitch length is still incorrect, repeat steps 1-3 until the stitch length is correct.

By following these steps, you should be able to easily fix incorrect stitch length with your PFAFF sewing machine.

Here you can find all the parts and accessories for the PFAFF Sewing Machine guaranteed to fit your sewing machine

Incorrect Stitch Width with PFAFF

Incorrect stitch width is a common issue when using a PFAFF sewing machine. It can be caused by a variety of factors, including incorrect thread tension, incorrect needle size, or incorrect stitch length settings. Fortunately, it is relatively easy to fix this issue with a few simple steps.

Examples of Incorrect Stitch Width

Incorrect stitch width can manifest itself in a variety of ways. Some of the most common examples include:

- Stitches that are too wide or too narrow

- Stitches that are uneven or inconsistent

- Stitches that are too loose or too tight

Step-by-Step Instructions for Fixing Incorrect Stitch Width with PFAFF

Follow these steps to fix incorrect stitch width with a PFAFF sewing machine:

- Check the thread tension. If the tension is too tight, the stitches will be too narrow. If the tension is too loose, the stitches will be too wide. Adjust the tension as needed.

- Check the needle size. If the needle is too small, the stitches will be too narrow. If the needle is too large, the stitches will be too wide. Replace the needle with the correct size.

- Check the stitch length setting. If the stitch length is too short, the stitches will be too narrow. If the stitch length is too long, the stitches will be too wide. Adjust the stitch length as needed.

- Test the stitch width on a scrap piece of fabric. If the stitch width is still incorrect, repeat steps 1-3 until the desired stitch width is achieved

Machine Not Properly Threaded: PFAFF

When a PFAFF sewing machine is not properly threaded, it can cause a variety of issues, such as skipped stitches, tension problems, and even jamming. Fortunately, it is relatively easy to fix this issue. Here are the steps to properly thread a PFAFF sewing machine.

Step-by-Step Instructions

- Raise the presser foot and the needle to their highest positions.

- Thread the needle from the front to the back, making sure the thread is in the groove of the needle.

- Pull the thread through the thread guide at the top of the machine.

- Pull the thread through the tension discs.

- Pull the thread through the take-up lever.

- Pull the thread through the thread guide at the back of the machine.

- Pull the thread through the thread guide at the front of the machine.

- Pull the thread through the thread guide at the side of the machine.

- Pull the thread through the needle plate.

- Pull the thread through the thread guide at the bottom of the machine.

- Pull the thread through the thread guide at the top of the machine.

- Pull the thread through the thread guide at the back of the machine.

- Pull the thread through the thread guide at the front of the machine.

- Pull the thread through the thread guide at the side of the machine.

- Pull the thread through the needle plate.

- Pull the thread through the thread guide at the bottom of the machine

Tips for Preventing PFAFF Sewing Machine Tension Problems

Regular Maintenance

- Clean the machine regularly, including the bobbin case and feed dogs.

- Check the tension discs for any signs of wear or damage.

- Replace the needle regularly, as a worn needle can cause tension problems.

- Check the bobbin case for any signs of wear or damage.

- Check the threading of the machine for any knots or tangles.

Adjusting the Tension

- Adjust the tension dial to the recommended setting for the type of fabric you are using.

- Check the tension of the thread by pulling it gently. It should be neither too loose nor too tight.

- If the tension is too tight, loosen the tension dial slightly and re-thread the machine.

- If the tension is too loose, tighten the tension dial slightly and re-thread the machine.

Using the Right Thread

- Use the correct type of thread for the fabric you are using.

- Check the thread for any knots or tangles before threading the machine.

- Use a high-quality thread for best results.

Using the Right Needle

- Use the correct type of needle for the fabric you are using.

- Check the needle for any signs of wear or damage before using it.

- Replace the needle regularly.

PFAFF Sewing Machines Manuals

PFAFF Sewing Machines Manuals & Updates here.

Here you can find all the Manuals for the PFAFF Sewing Machine guaranteed to fit your sewing machine

10 Common Problems with PFAFF Sewing Machines

In addition to the common problems listed above, PFAFF sewing machines can also experience the following issues:

- Stitch Problems

- Sewing Machine Parts Problems

- Upper thread breaking

- Breaking needles problems

- Bobbin winding problems

- Bobbin thread problems

- Bobbin holder problems

- Bobbin tension problems

- Sewing Machine Keep Jamming

- Sewing machine not feeding fabric

FAQ

What is the most common cause of tension problems?

The most common cause of tension problems is incorrect threading of the machine. If the thread is not properly threaded through the tension discs, the tension will be off and the stitches will not be even.How can I adjust the tension on my PFAFF sewing machine?

The tension on a PFAFF sewing machine can be adjusted by turning the tension knob on the top of the machine. Turning the knob clockwise will increase the tension, while turning it counterclockwise will decrease the tension.What should I do if my stitches are still uneven after adjusting the tension?

If your stitches are still uneven after adjusting the tension, it could be due to a number of other factors. Check the needle size and type, the thread type and weight, and the fabric type and weight to make sure they are all compatible. If the problem persists, it may be necessary to take the machine to a professional for servicing.What are some other common causes of tension problems?

- Incorrect needle size or type

- Incorrect thread type or weight

- Incorrect fabric type or weight

- Incorrect bobbin tension

- Dirty or worn machine parts