SINGER M1500 Sewing machine breaking needles

Using the wrong size needle, attaching the presser foot or attachment improperly, pulling fabric while sewing, employing a needle that is too short or long, failing to secure the needle in the needle bar and stitching over pins at an angle can all cause SINGER M1500 sewing machine needles to bend and break.

This can result in unsatisfactory stitch quality and damage to your of SINGER M1500 sewing machine. To avoid this, ensure that needles are of proper size, properly fastened, and free from any obstructions before starting a project.

Here you can find all the parts and accessories for the SINGER M1500 guaranteed to fit your sewing machine

Why break needles on the sewing machine SINGER M1500?

If your SINGER M1500 sewing machine needle keeps breaking, you may need to investigate what is causing the issue instead of simply replacing it. There are various possible explanations for why a needle can break and a few fixes that you can attempt to resolve the problem. If any damage, no matter how small, is noticed on the needle then it should be changed in order to prevent disruption to your sewing.

Common Problems Causing A Needle Break in Sewing Machine SINGER M1500

There are 5 main problems that can cause a needle to break in a SINGER M1500 sewing machine:

- The needle on sewing machine SINGER M1500 is damaged, bent

- The needle on sewing machine SINGER M1500 is Dull

- Incorrect needle size for fabric

- Wrong SINGER M1500 sewing machine thread tension

- The wrong SINGER M1500 sewing machine presser foot is attached

Needle breakage can be caused by several problems with the SINGER M1500 sewing machine, so let’s explore them:

The needle on sewing machine SINGER M1500 is damaged, bent

When using a SINGER M1500 sewing machine, it is important to inspect the needle for any signs of damage or wear before beginning to sew. If needed, replace the needle with a sharper one. Working on heavier fabrics may cause strain on a worn or bent needle, resulting in breaking while stitching. Slowing down the stitching speed can also help prevent unnecessary damage.

The needle on sewing machine SINGER M1500 is Dull

The needle on the SINGER M1500 sewing machine should be inspected regularly to ensure that it is sharp and intact. To test if the needle is dull, you can use a pocket knife blade to scratch against it; if there is resistance, then it’s time for a replacement.

Depending on how much the SINGER M1500 sewing machine is used, needles should typically be changed every 8-10 hours of use to prevent skipped stitches, uneven lengths and poor quality seams. Taking care of your needle will help you create beautiful and professional looking projects that last long. If any sign of damage or dullness appears, replace the needle immediately.

How to check the needle on a SINGER M1500 sewing machine

To make sure your SINGER M1500 sewing machine needle is in optimal condition, it’s essential to check for a bend before use. Put the flat part of the needle on a level surface and confirm that both sides are even. If you find that your needle has been bent, do not attempt to sew with it!

A crooked or damaged tool could break while operating, causing harm to yourself and others nearby. To avoid this risk altogether, only utilize needles specifically designed for home sewing machines— doing so will guarantee they remain safe during usage.

(1) Flat side (2) Needle type marking

– Correct needle

(3) Parallel space (4) Flat surface

– Incorrect needle

If the needle is not even with the flat surface, it is bent. Do not use a bent needle.

(5) Flat surface

Here you can find all the parts and accessories for the SINGER M1500 guaranteed to fit your sewing machine

Incorrect needle size for fabric

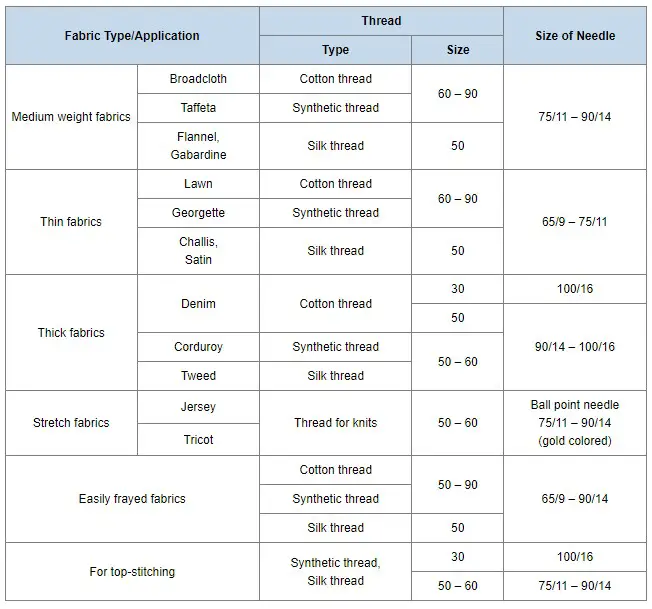

When sewing with different fabrics, the size of the needle is key. If you use a too-large needle for the fabric type, it can cause excessive friction that could lead to the needle breaking. To ensure that you are using the correct needle size, look up its recommended size based on thread and fabric thickness in the Singer M1500 sewing machine manual. This will help to prevent needles from breaking and keep your projects looking their best.

Needle and thread combinations

Finding the perfect needle for your SINGER M1500 sewing machine requires evaluating factors such as thread and fabric type. Utilize the provided chart to discover suitable pairings of needles, threads, and fabrics that will guarantee flawless results!

Important to know:

- Forging an improper combination like thick fabric such as denim with a small needle (e.g., 65/9 – 75/11) can be hazardous and cause potential harm, since the needle may break or bend when sewing. Additionally, it could yield irregular stitches that do not look uniform at all.

- Avoid using thread of weight 20 or below at all costs as it can result in an array of undesirable problems.

- For a secure and smooth stitch, choose a ball point needle (golden-hued) when working on stretch fabrics or materials that tend to overlook stitches.

- No matter what your fabric and thread type are, a needle size of 90/14 to 100/16 is the perfect choice when using transparent nylon thread.

- The lesser the thread number, the stronger its structure; and correspondingly, a larger needle number indicates thicker needles.

Here you can find all the parts and accessories for the SINGER M1500 guaranteed to fit your sewing machine

Wrong SINGER M1500 sewing machine thread tension

Thread tension is a crucial factor when sewing, as it helps avoid needle breakage. It should be adjusted depending on the weight of the fabric and thread being used. Both the upper and lower threads should also have equal weight to ensure that correct tension is applied to prevent needles from bending or snapping. This will help you get better results with your SINGER M1500 sewing machine.

The wrong SINGER M1500 sewing machine presser foot is attached

Using improper or incompatible presser foot with a SINGER M1500 sewing machine can cause needles to become damaged due to repeated strikes against it. To minimize risk, ensure that the right type of presser foot is used for each pattern and double-check that all corresponding settings are correctly adjustedcisely worded. This will protect needles from damage and help maintain good results.

Conclusion

In conclusion, needle breakage on a SINGER M1500 sewing machine can be prevented by selecting the right type of needle for your fabric, adjusting the thread tension correctly according to the material, and ensuring that the correct type of presser foot is being used for each pattern.

By following these steps, you can protect your SINGER M1500 sewing machine needle from unnecessary breakage and ensure that it performs optimally. This will reduce the need for costly replacements and keep your sewing projects running smoothly. With proper care and maintenance, your SINGER M1500 sewing machine can guarantee flawless results!